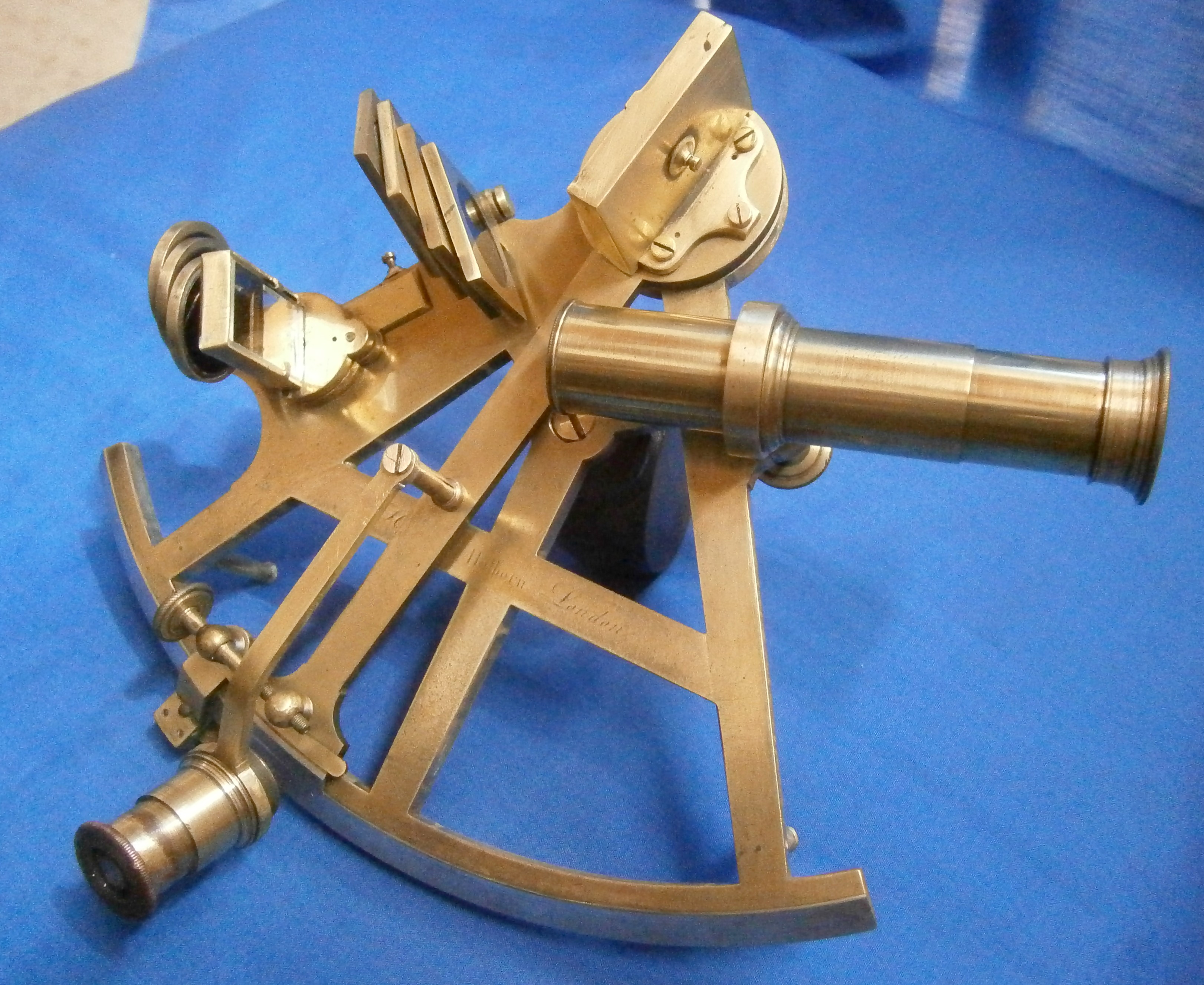

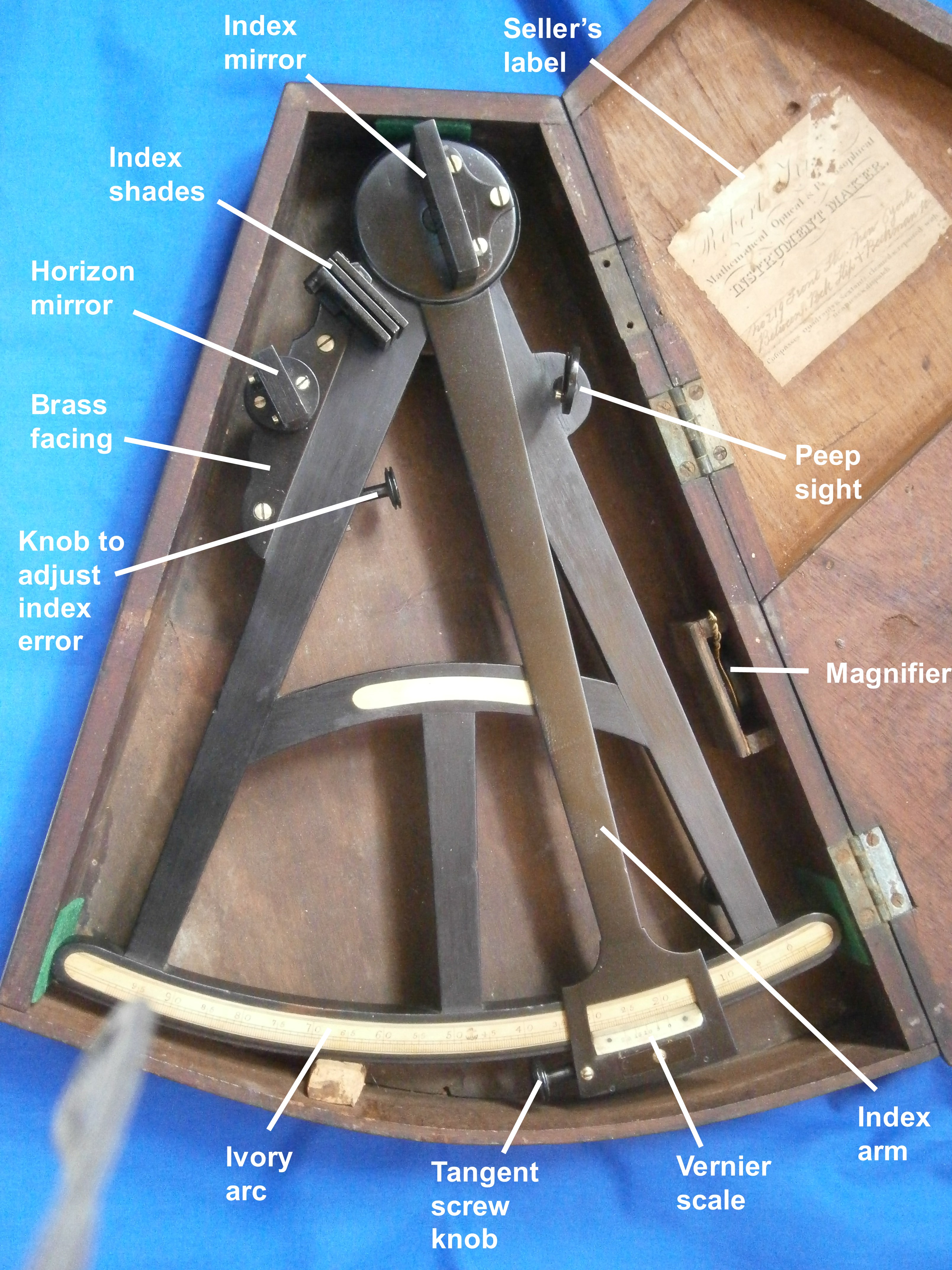

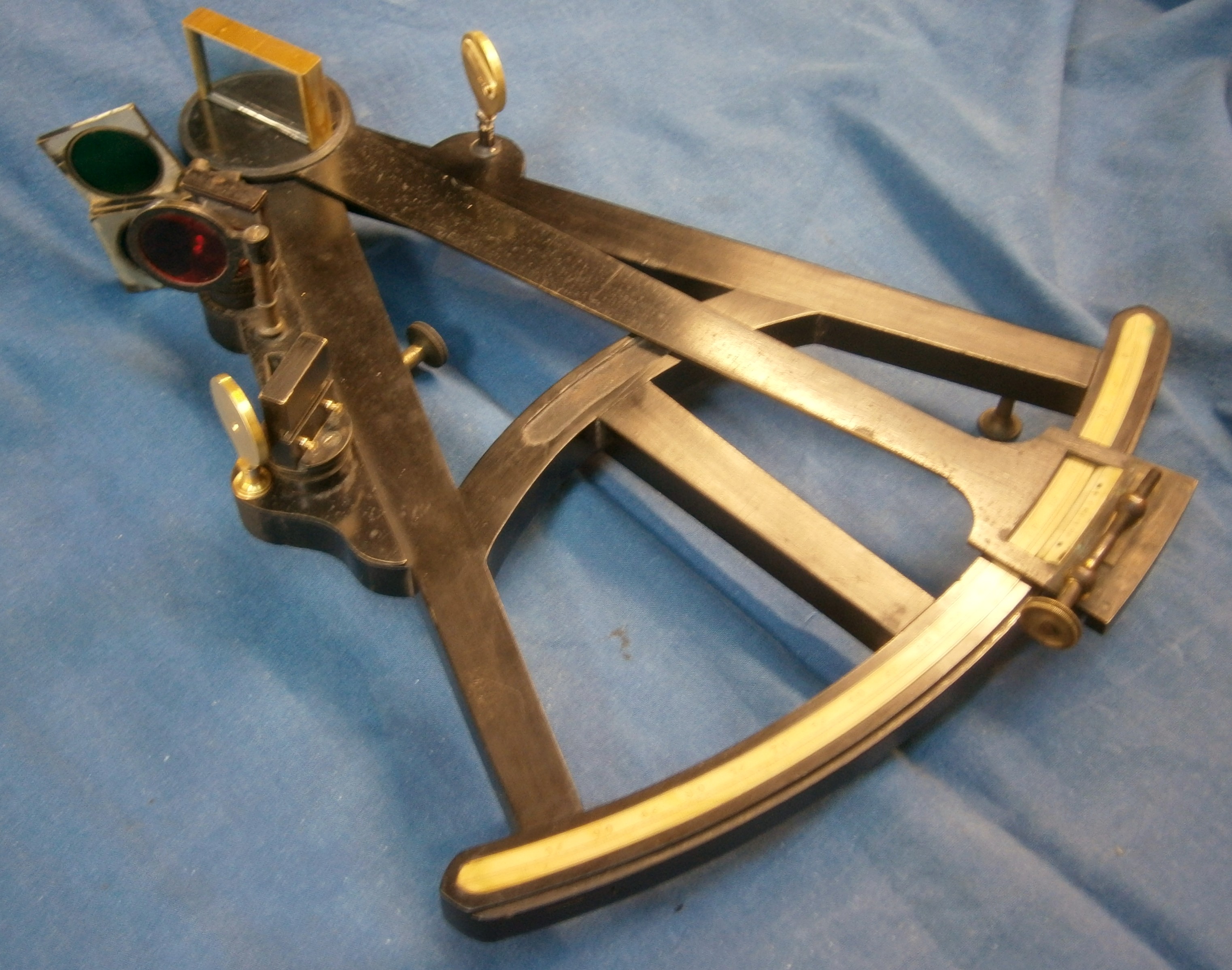

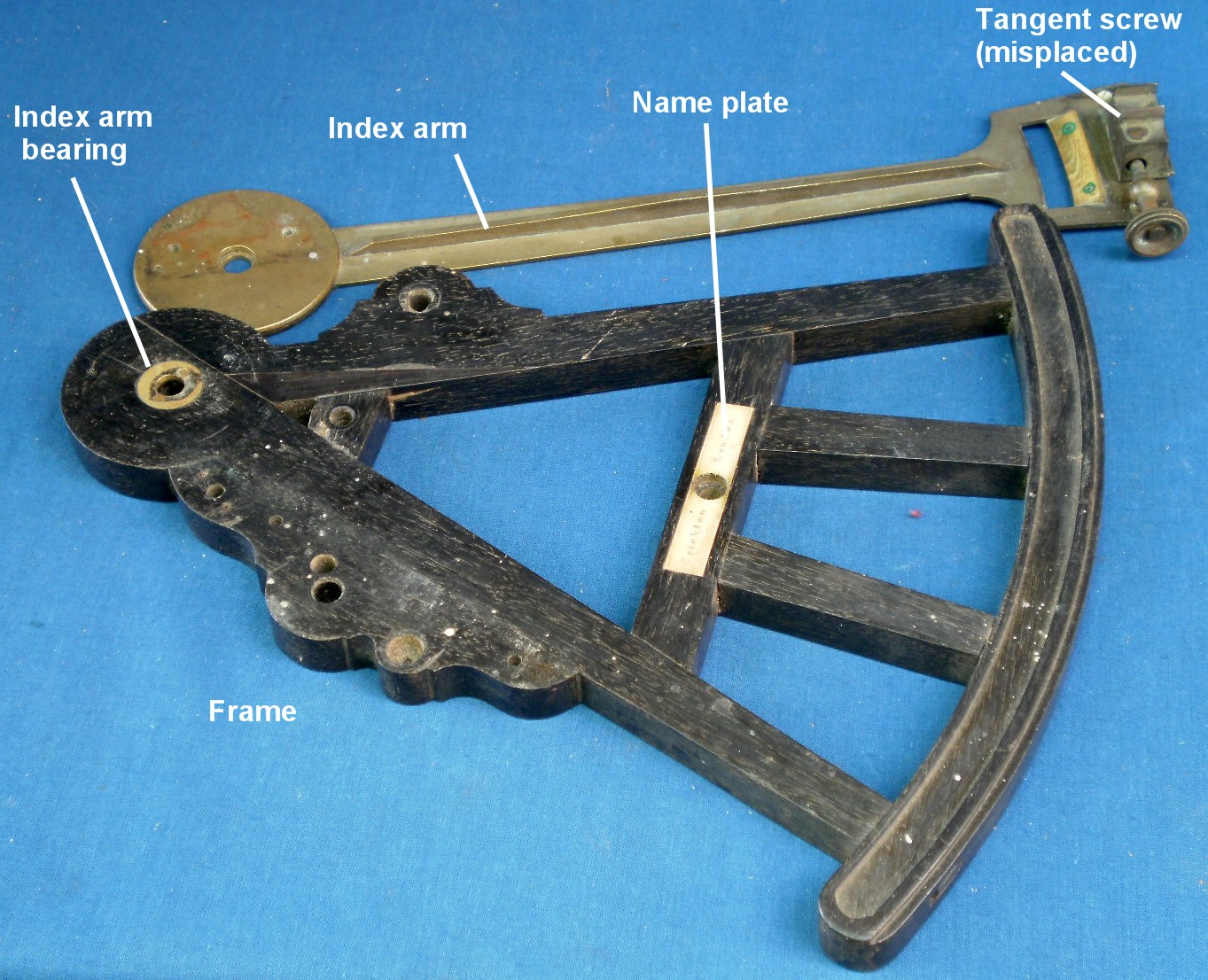

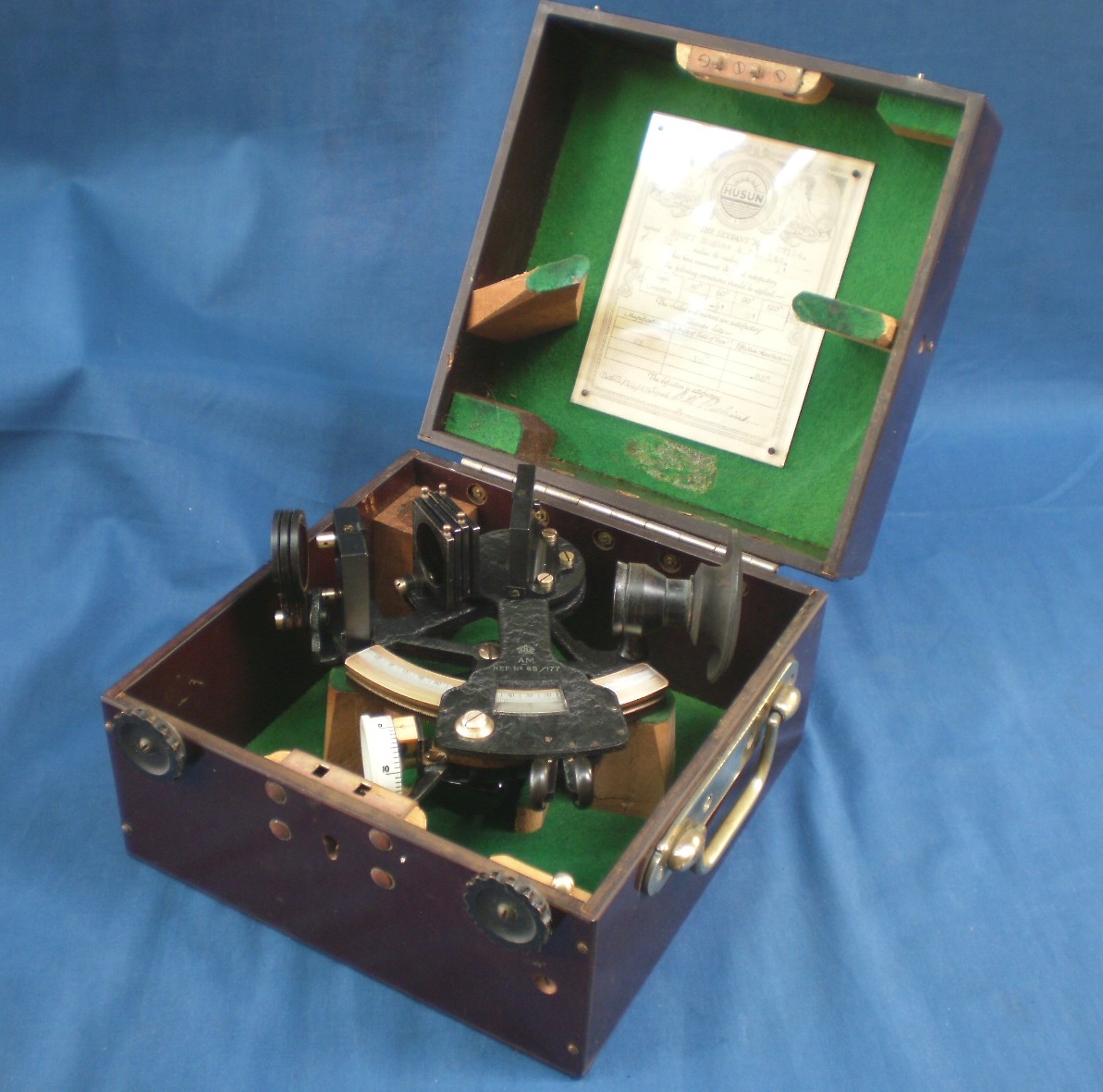

During a lock-down period for Covid 19 in 2021, a large box arrived from a collector in Australia. In it were four antique sextants and a circle which Dave wished me to restore for him and over the intervening months I did just that. A few weeks ago, when New Zealand opened its gates again to overseas visitors, he came to visit his mother, and also made the trip up to the Far North to collect his instruments. During his visit, he was able to look over my few late eighteenth and early nineteenth sextants, and before he left he entrusted me with another sextant and a small box of spare parts, in the hope that I could restore it for display rather than actual use. Figure 1 shows the front or left-hand side of the instrument as received except for the index mirror bracket, which I had cleaned and painted before I had thought about photographing it. I had also removed heavy tarnishing from the scales by dint of patient rubbing with ammonia solution.

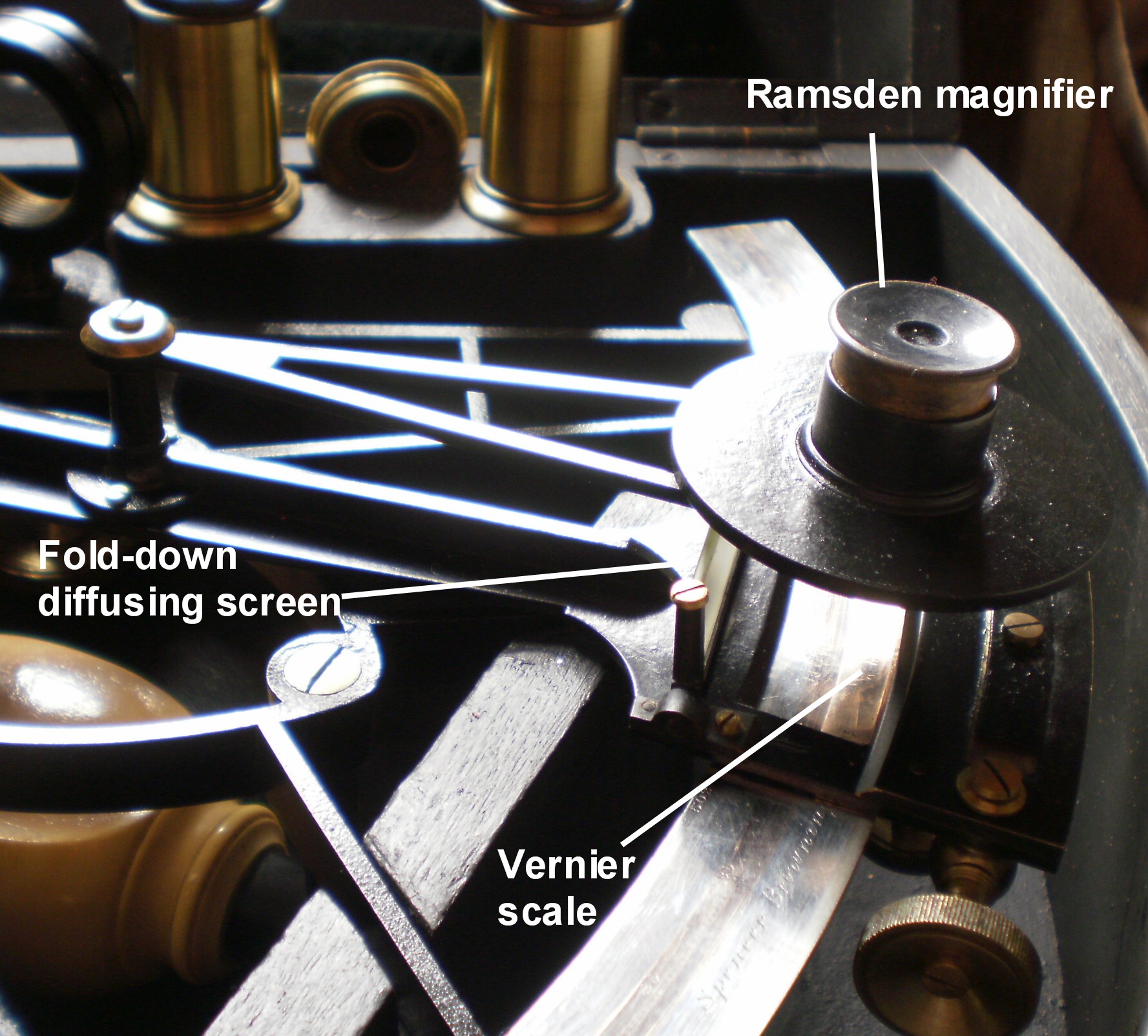

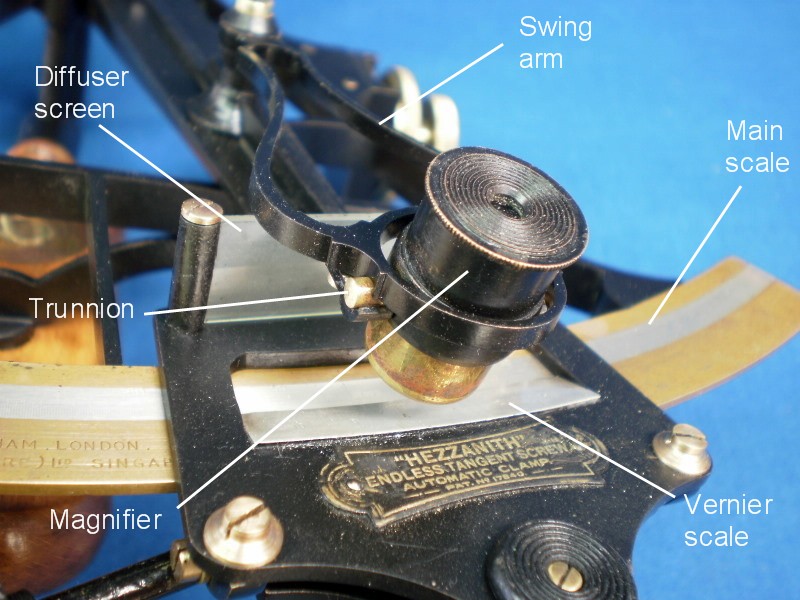

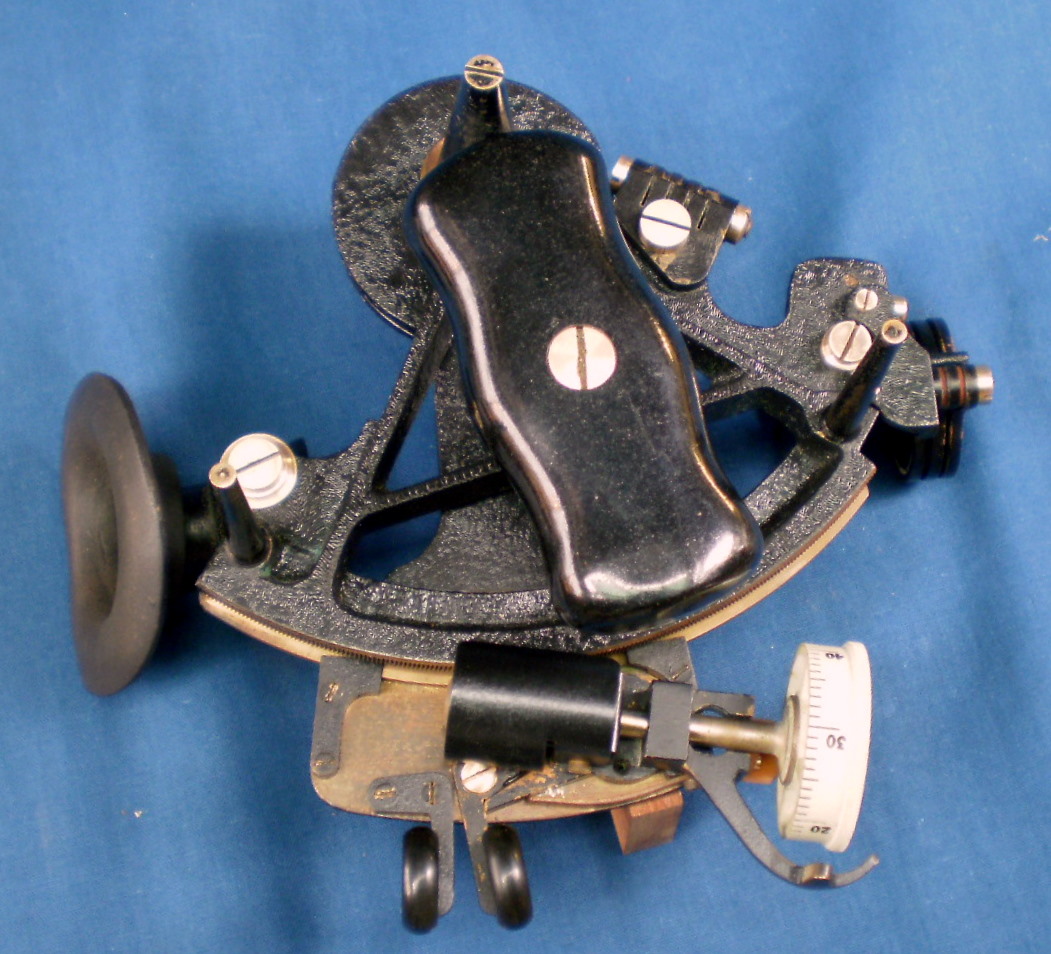

Missing is any form of sighting device, the index mirror bracket, all the horizon shades, the tangent screw assembly and the shade screen for the vernier scale. A thumb screw half way down the index arm marks where a magnifier arm for reading the scales was no doubt placed. Figure 2 shows the rear or right-hand side as found.

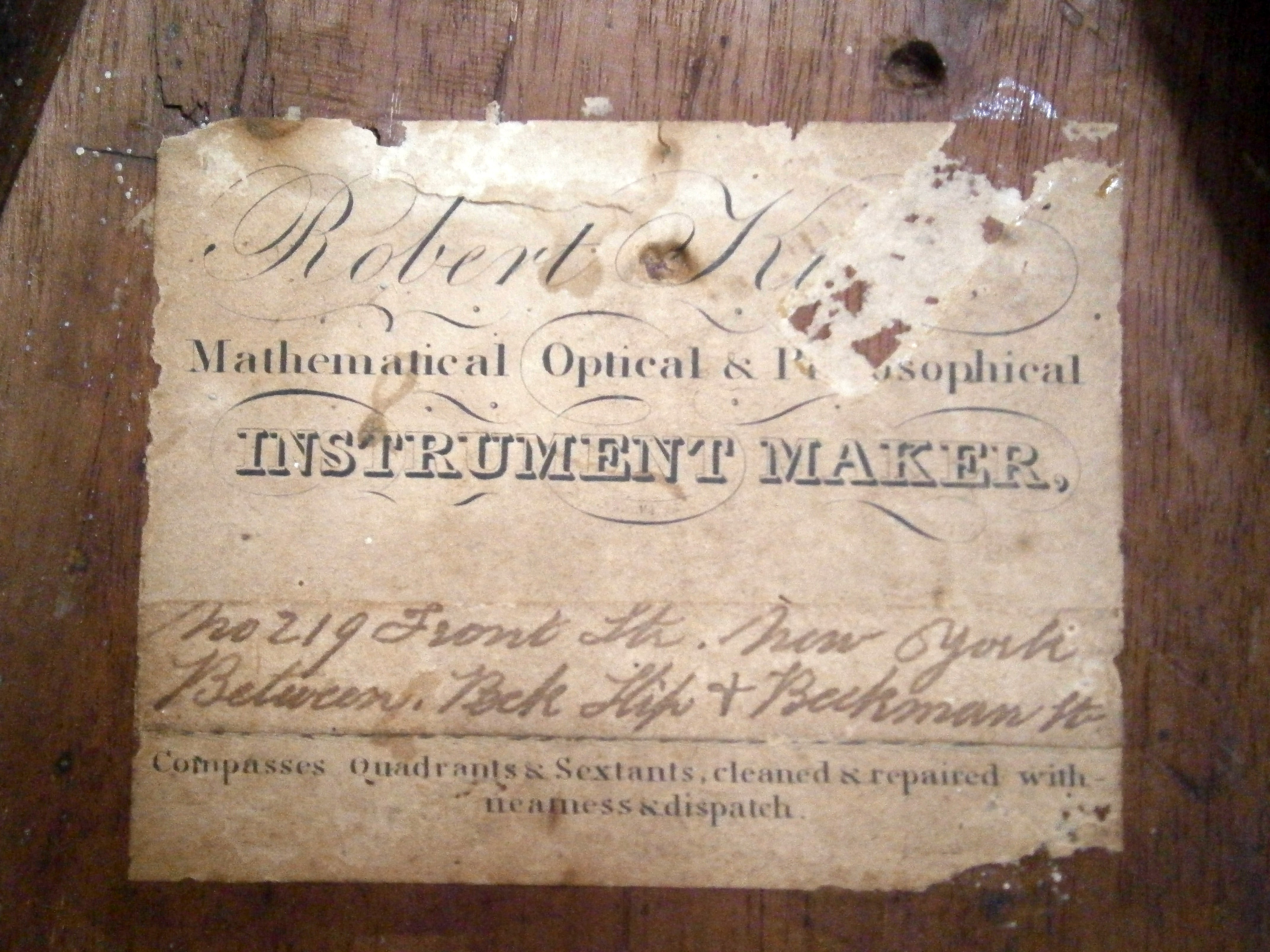

It is somewhat unusual to find a silver-in-brass arc married to a wooden frame, in this case of heart ebony, a strong, dense and stable African hardwood. More usually, wooden framed sextants have ivory arcs glued in a rebate on the front of the limb, while early metal-framed sextants commonly had ivory arcs inlaid. Figure 3 shows one of the nine rivets that attach the arc to the frame and the maker’s name. I have not been able to find any details of Védy of Paris or indeed, whether he was a maker or merely a retailer. The fact that the instrument is numbered suggests the former. Perhaps some reader can tell me more?

The dividing of the scale is of high quality and it is known that Bochard de Saron acquired Jesse Ramsden’s first dividing engine in 1775 and made it available to French artisans until he literally lost his head in April, 1794, during the French Revolution. The state then continued to make it available to instrument makers, including the leading maker, Etienne Lenoir.

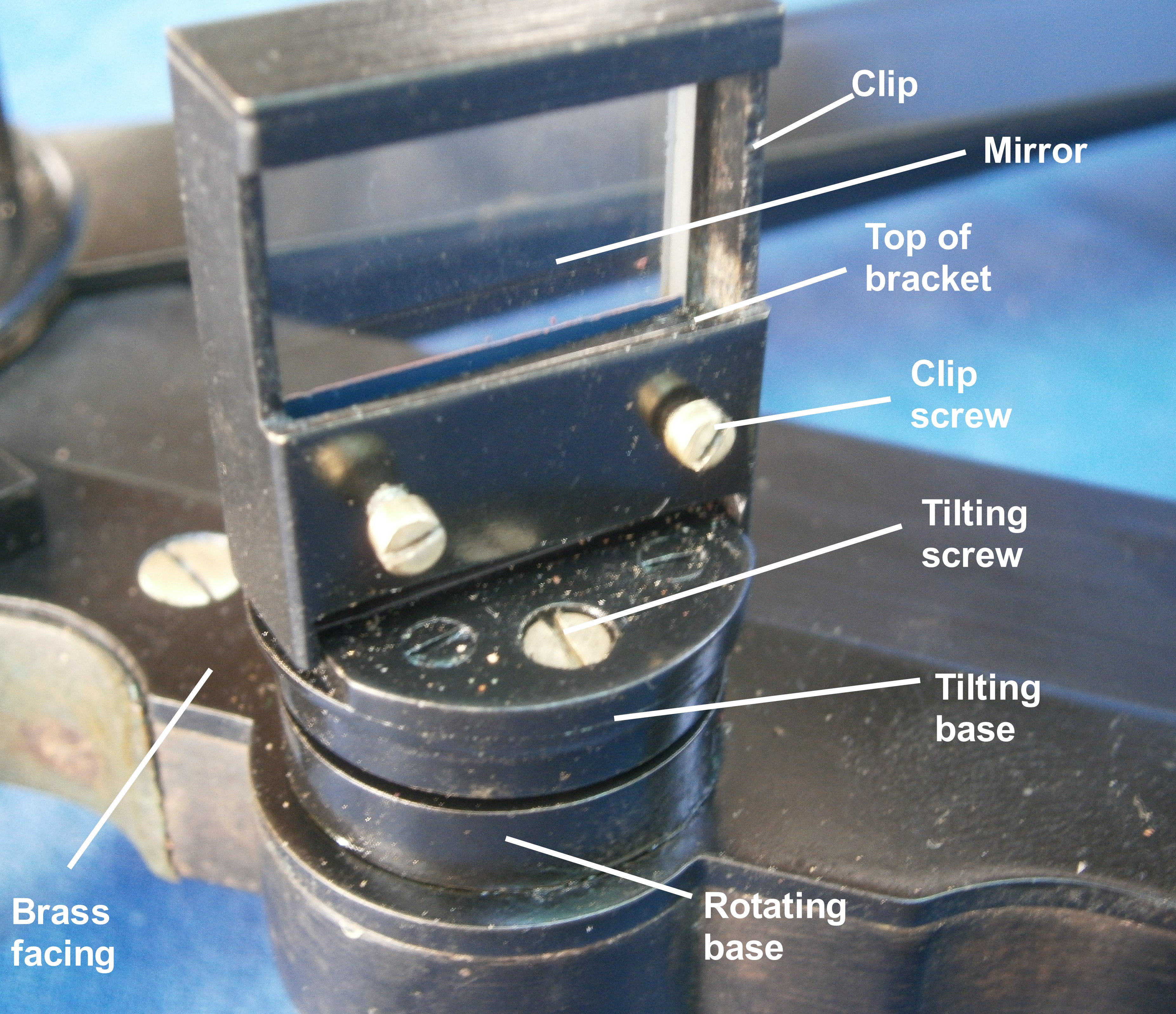

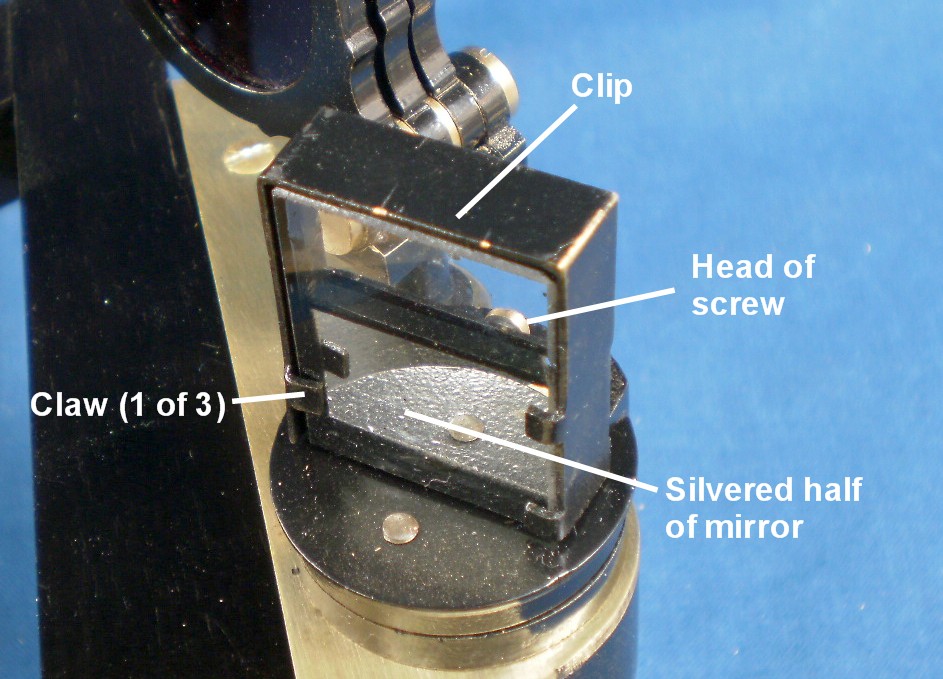

The mirror adjustments are complex and archaic at a time when most sextants of English manufacture had adopted the simpler method described by Peter Dolland in 1772 in a letter to the Astronomer Royal, Nevil Maskelyne, and published in Phil. Trans. 1772 62, 96 – 98. It was also described in Patent no. 1017 of 22 May 1772. “I have contrived the frame , so that the glass lies on three points, and the part that presses against the front of the glass has also three points exactly opposite to the points between which the glass is placed. This contrivance may be of some use; but the principal improvements are in the methods of adjusting the glasses,...” The method not only removes stresses in the mirror but also allow for simple adjusting of perpendicularity of the index mirror and removal of side and index error at the horizon mirror.

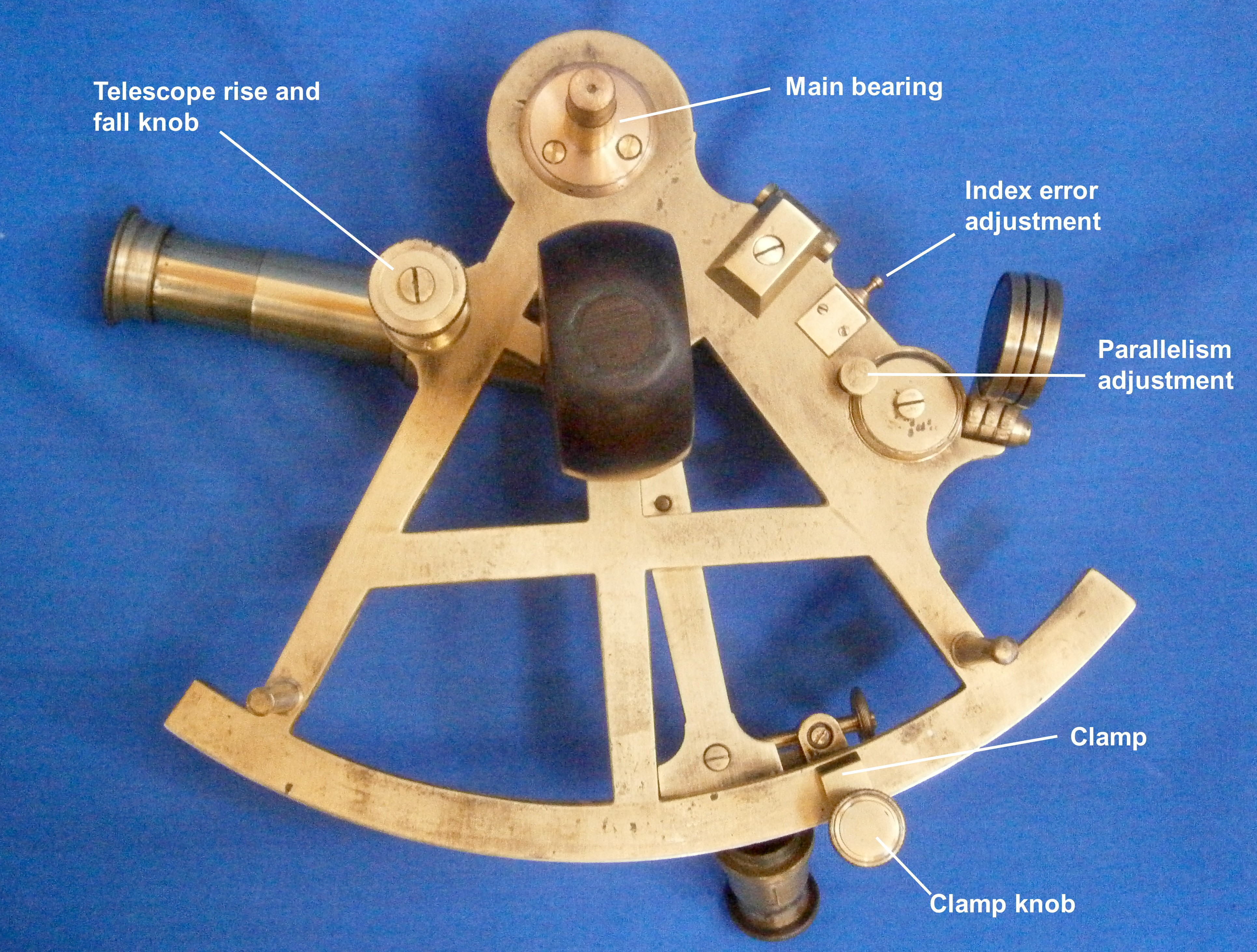

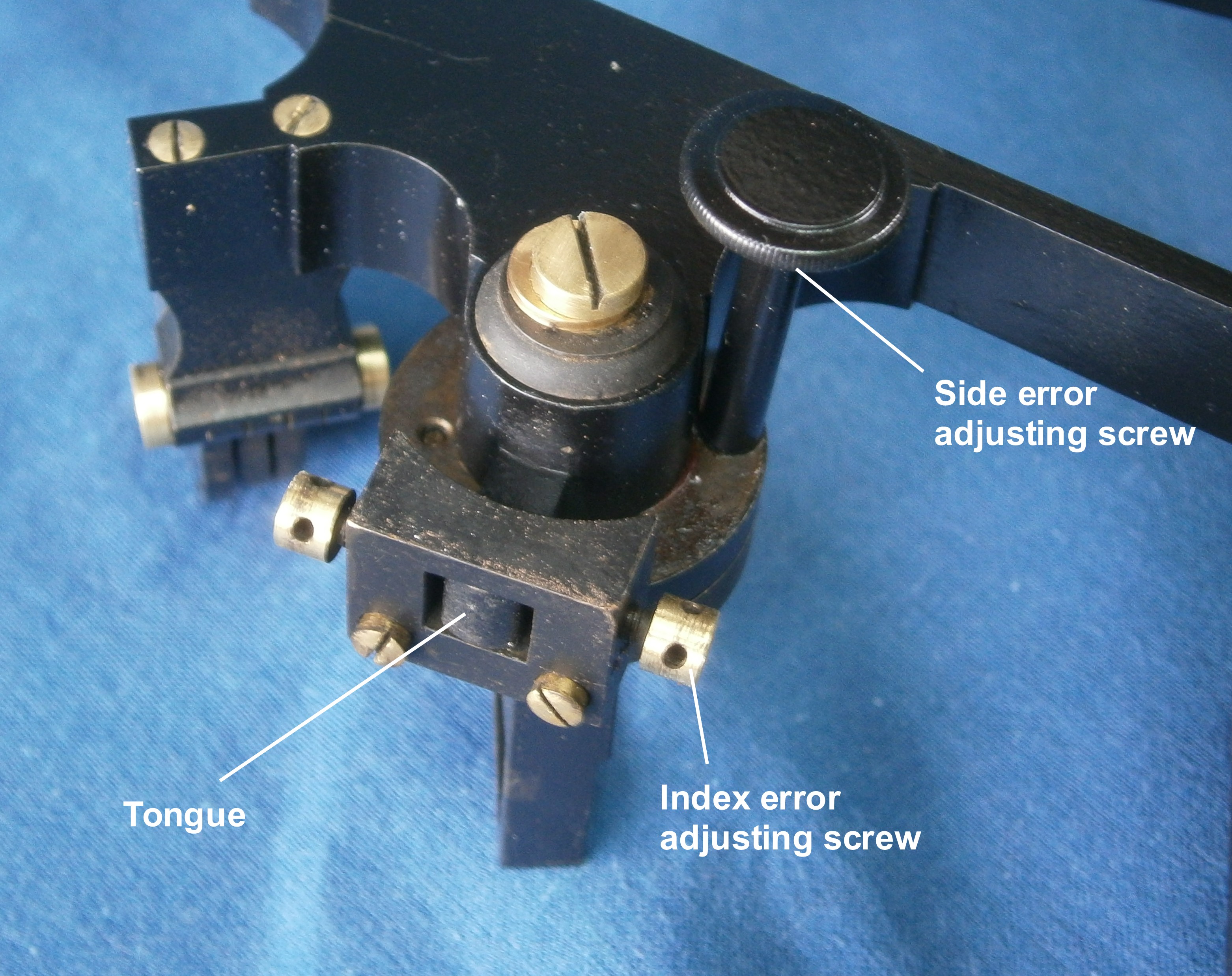

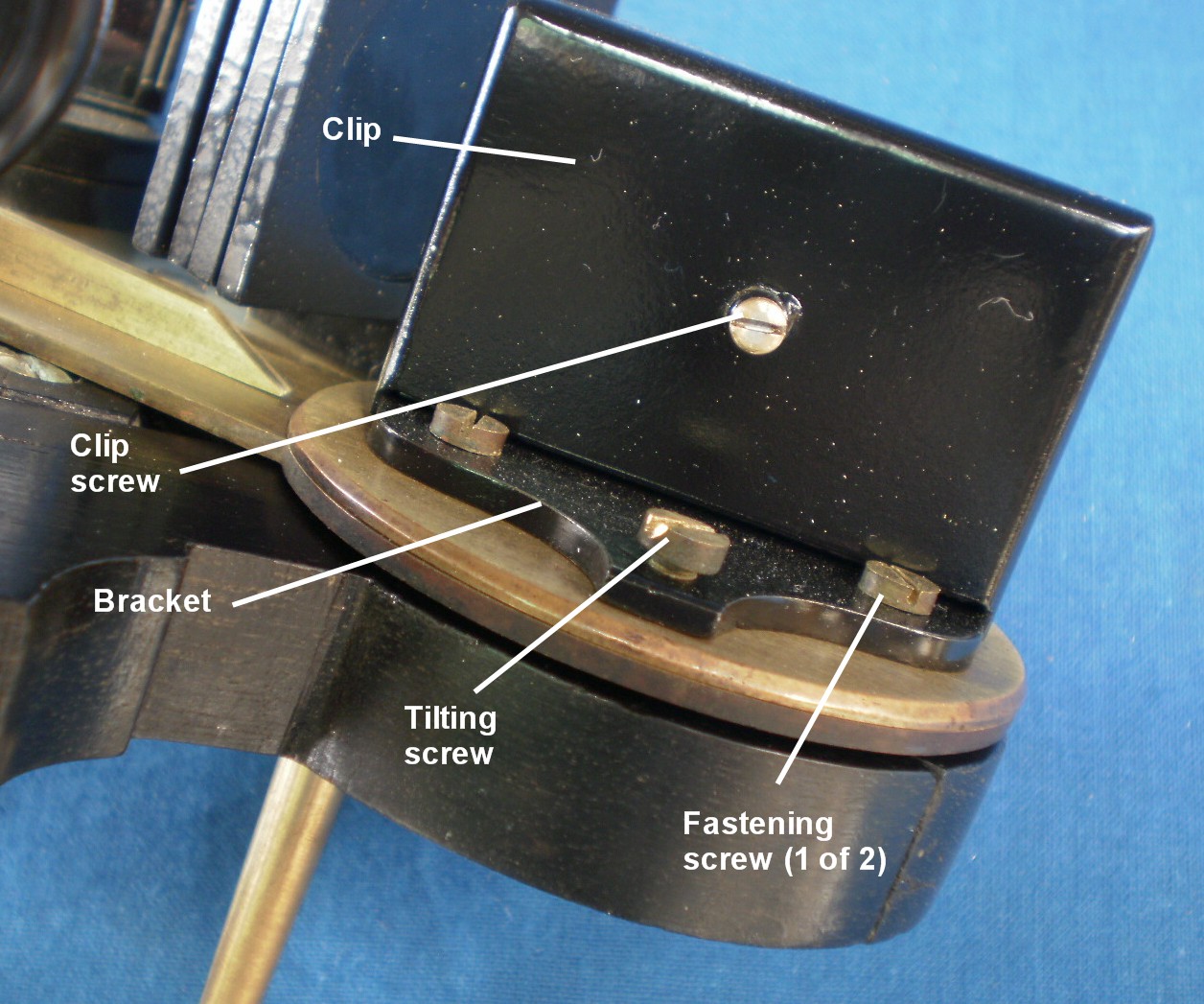

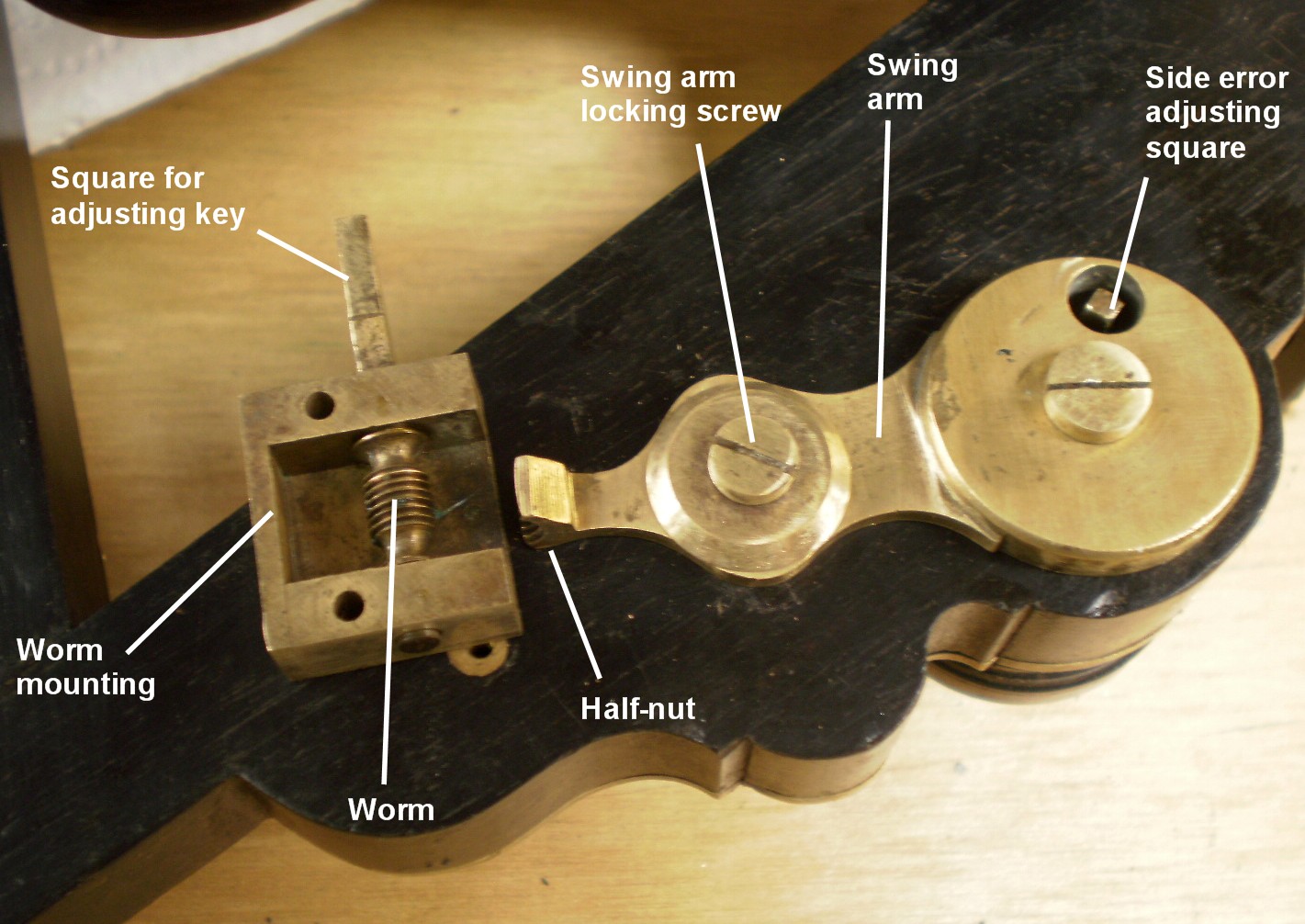

Figure 4 shows the means of adjusting out side error. The horizon mirror is held against a vertical bracket on top of a round base by means of a clip and two screws. The base is hinged on to a rotating base the shaft of which extends through the frame to a means of adjustment to be described below. An adjusting screw operates against a spring that surrounds it, allowing the base to be tilted and the mirror made parallel to the index mirror.

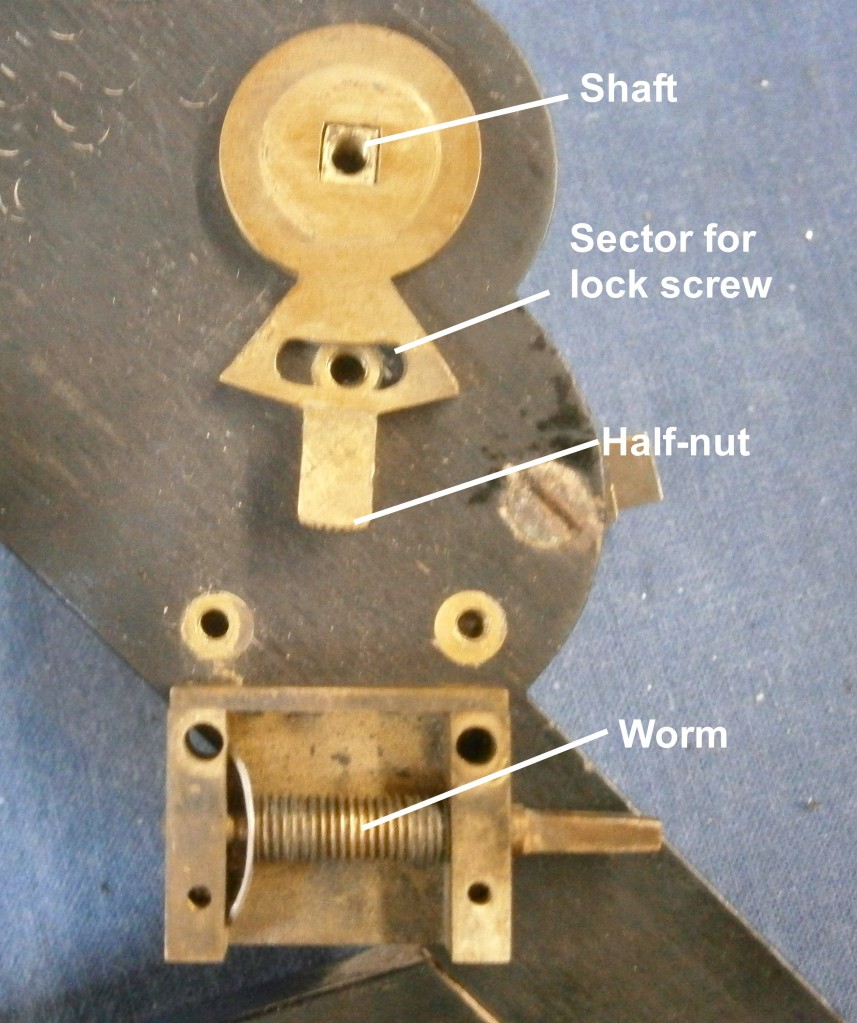

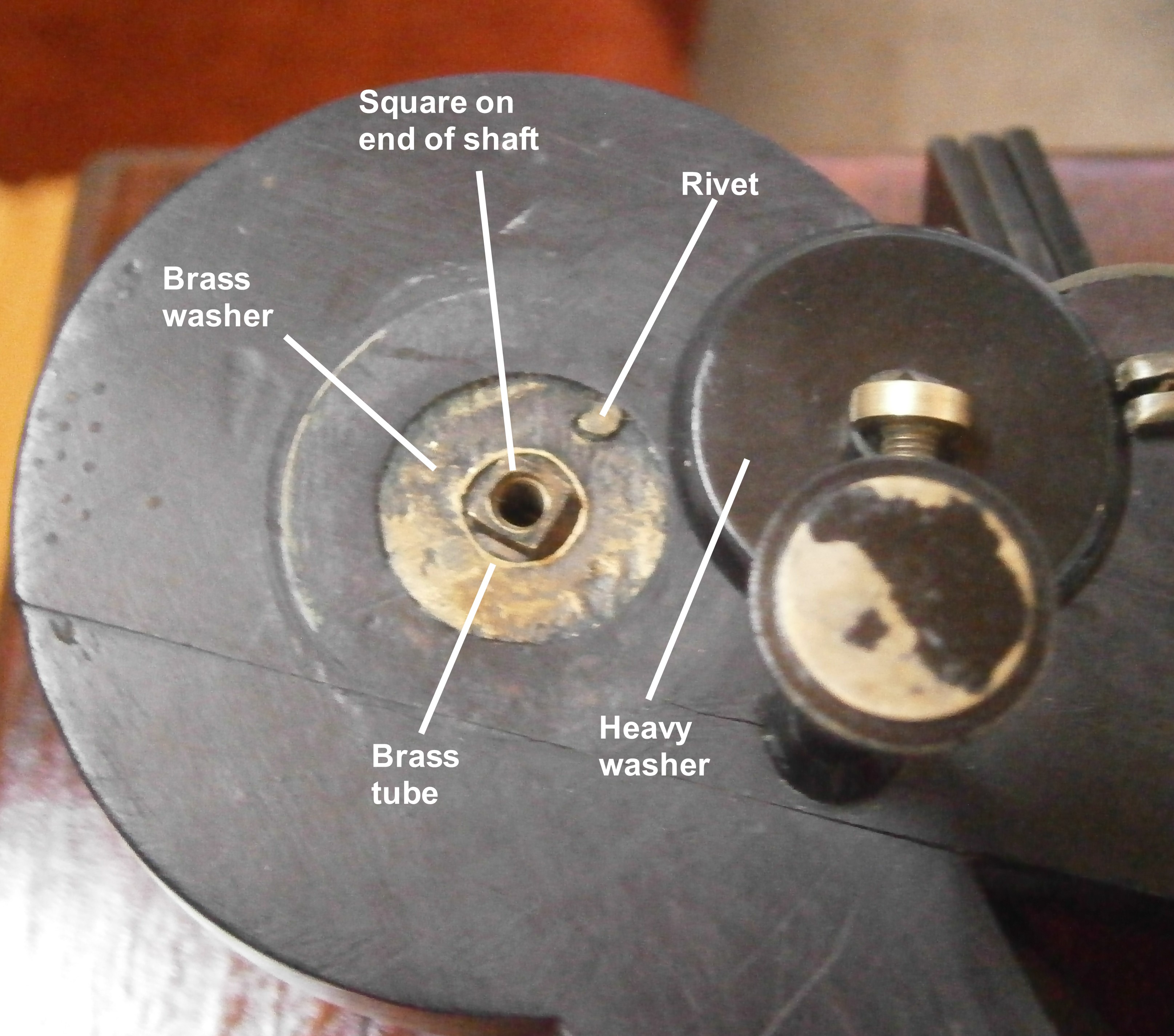

Figure 5 shows the end of the shaft of the rotating base. It is connected via a square on the end of the shaft to a sector that has a half-nut on its end which engages with a worm inside a fabricated brass box. The sector is retained on the shaft by a screw with a large head(not shown). The worm box is attached to the frame by means of two screws which engage with two threaded brass bushes let into the frame. The sector can be locked in place by means of a clamp screw. Rotating the squared end of the worm shaft in turn rotates the rotating base and allows fine adjustment of the index error. Figure 6 shows the assembly exploded.

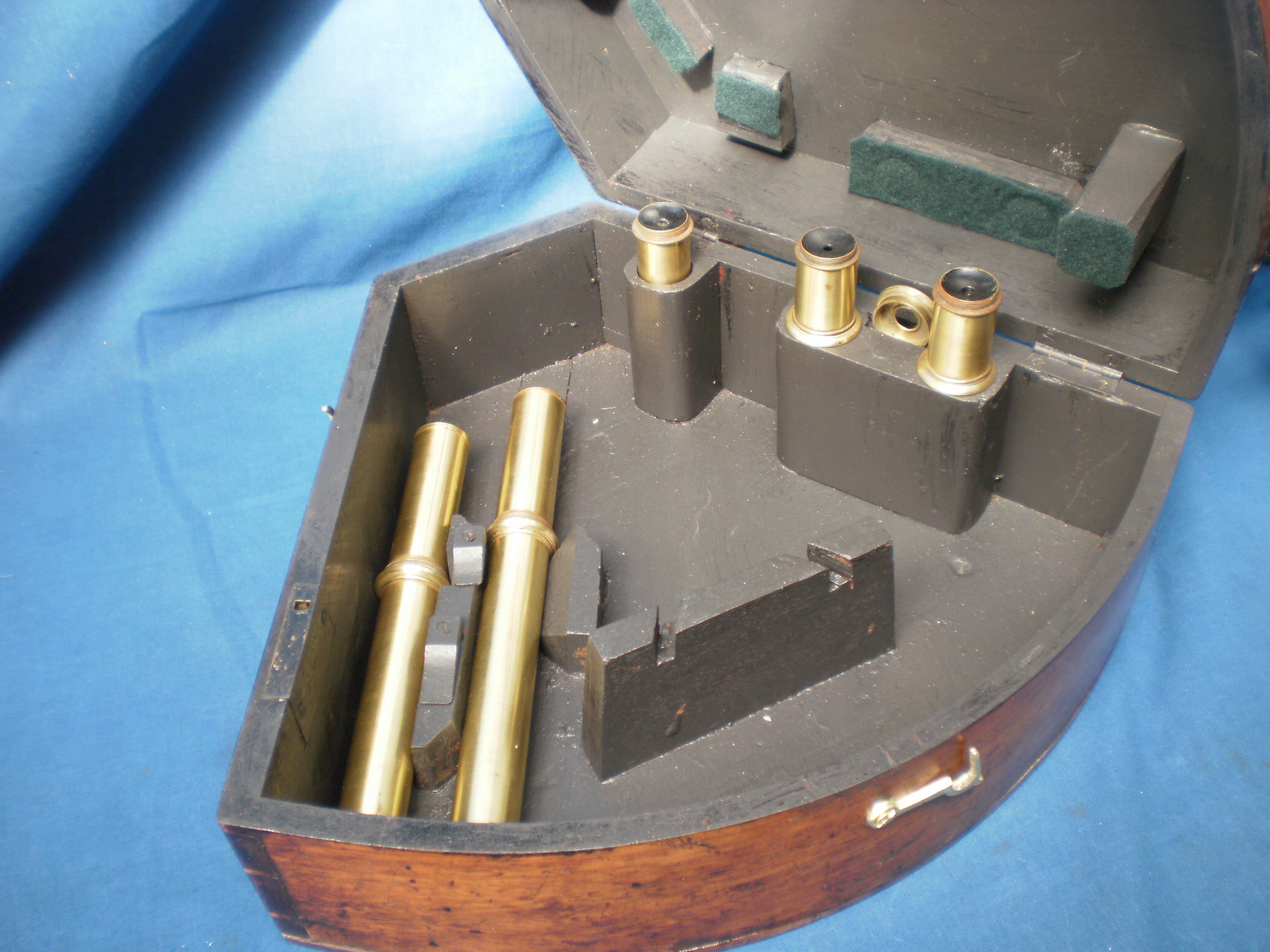

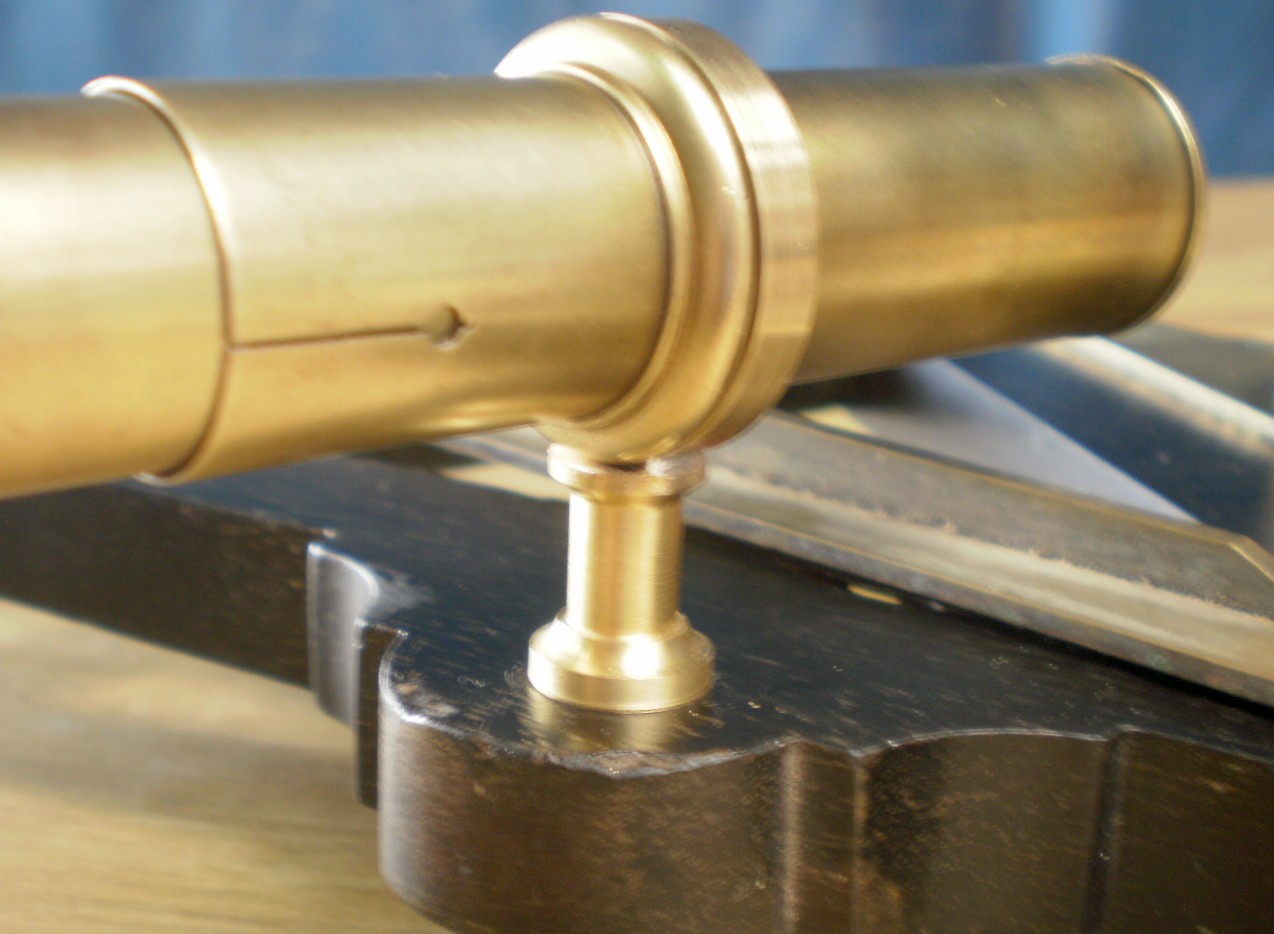

In the box of possible spare parts was a sighting tube. Happily, the thread on its body was of a larger outside diameter and of a different pitch to the internal diameter of the existing telescope rising piece, so I was able to turn it down and cut a new matching internal thread. I was able to ascertain the pitch of the latter by pressing a piece of Plasticene into the thread, removing it and then using an engineering microscope to measure the impressed thread.

Figure 7 shows the telescope mounting. Avid readers of this blog will have noticed the similarity of the mounting to that shown in Figure 1 of my post of October, 2021, on a reflecting circle. This does not necessarily mean that the two instruments were contemporary, but rather that apprentices would copy masters, sometimes over several generations, or specialist makers of small parts would supply to “makers”, who were assemblers and finishers, rather like modern automobile manufacturers.

Figure 8 shows the mounting exploded. A large knurled nut holds a bush securely in the frame and the triangular stem of the rising piece slides in a triangular hole in the bush. A screw is held captive in the bush by means of a knurled thimble which has a square hole in it to match the square on the end of the screw. A countersunk screw(not shown) passes through the thimble into the end of the adjusting screw and tightening it secures the adjusting screw in the bush, allowing free rotation without up and down movement.

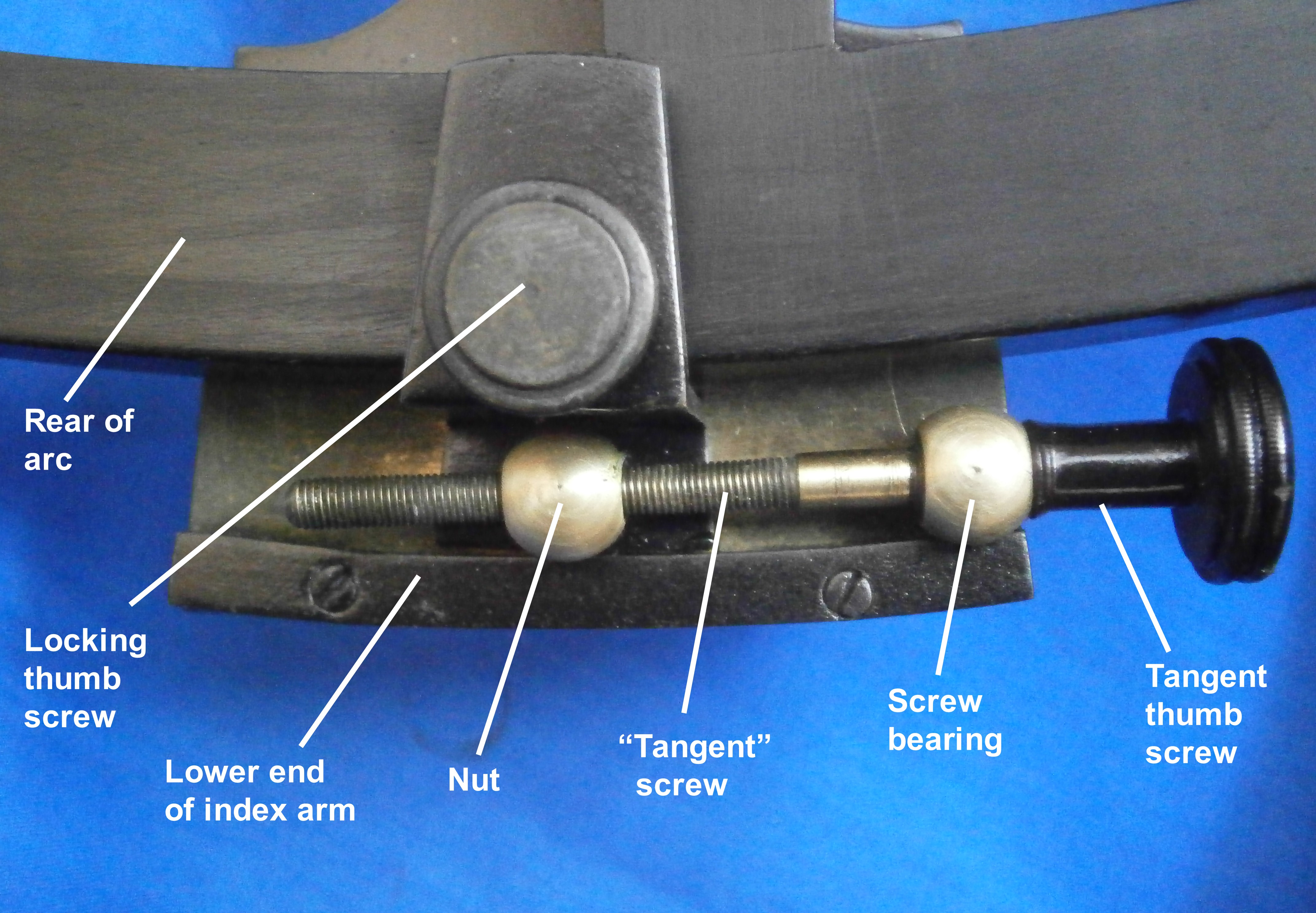

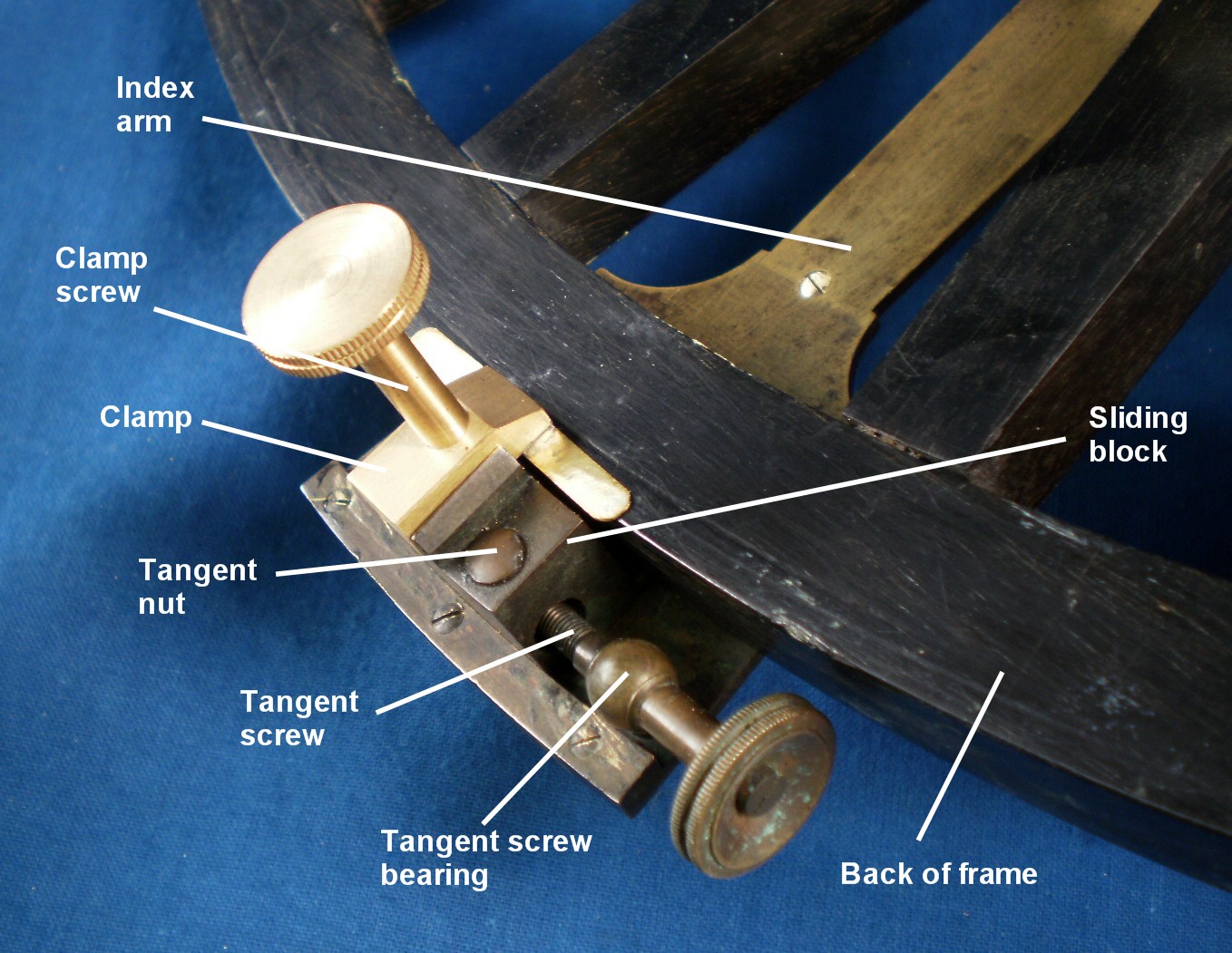

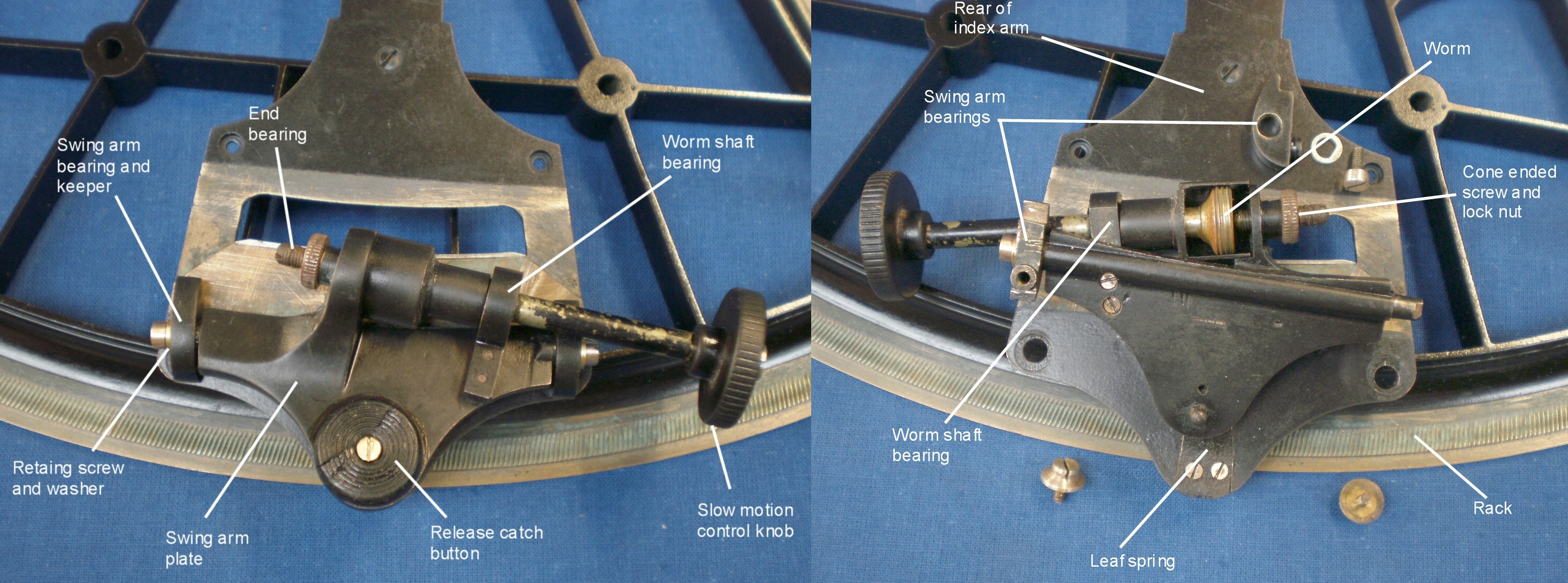

Reference to Figures 1 and 2 shows that the tangent screw with its nut and bearing were entirely missing, the sliding block was present and a mangled leaf spring remained. With the parts available, I was not able accurately to reproduce what was present before, but Figure 8 shows a closely similar appearance, the main difference being that the bearing was secured by means of a screw passing from the front of the index arm into its base. The original bearing was probably spherical and held in a spherical seat.

When the lock screw is tightened, the sliding block is locked to the limb and when the tangent screw is rotated the index arm slides over the block. When the lock is loosened, the index arm can be slid rapidly along the limb, while the leaf spring holds the arm in contact with the frame. The original spring and the little block that held it were too badly mangled to use and I had to make new ones. I resisted the temptation to use a piece of clock spring or a scrap of beryllium copper, and instead hammered a strip of brass to work harden it and make it springy as a contemporary artisan would have done. The resulting distortions had to be corrected by filing.

In the upper left of Figure 7 can be seen the way the index mirror is brought perpendicular to the plane of the arc. An adjusting screw with a square head is held captive in a tongue projecting from the index mirror bracket by means of a bar and two screws. There are two screws through feet securing the front of the bracket and their soles are slightly rounded to allow rocking as the adjusting screw is rotated in a threaded bush let into the top of the index arm. Peter Dollands invention, mentioned above, made these little complexities redundant. A mirror clip from the box of spare parts was easily modified with a file to fit the bracket.

There were three rather battered horizon shades in the box of parts and it was the work of a few minutes to make a shouldered screw and three washers to fit them into the existing bracket. I domed a further thin washer by placing it on the end grain of a scrap of wood, sitting a ball bearing in the hole and striking it hard with a hammer. This gave me a thin and stiff spring to adjust the friction when the screw was tightened. This type of spring washer is now known as a Belleville washer, patented in 1867 by Julien Belleville of Dunkirk. Fairly obviously, the principle was well known before that. A lock nut at the end of the screw then completed the assembly.

The index arm bearing followed the pattern shown in Figures 25 and 26 of my post for 11 March 2012 and it required only cleaning and greasing.

I used black laquer on brass surfaces, leaving screw heads bright as seems to have been the custom, and used black shoe polish to brighten the frame to complete the restoration.

The finished restoration is shown in Figures 10 and 11.

Postscript Murray Peake has kindly provided me with some details of the maker, Louis Félix Védy, 1811 – 1875. He was active in the middle of the nineteenth century and was a principle supplier to the Dépot de la Marine. He was made a Chevalier de la Legion d’Honneur in 1851. His apprentice master was Antoine-Francois Jecker, 1765 – 1834, who worked for six years under Jesse Ramsden.

You must be logged in to post a comment.