This post is preceded by “Inside the Freiberger Skalensextant” and “The Freiberger Skalensextant.”

Freiberger Präzisionsmechanik of the then German Democratic Republic, produced three sextants over the years: the uncommon Skalensextant; their main line, the Trommelsextant, aimed at professional navigators; and in the late 1970s they introduced their Yacht sextant. The latter was aimed at “Western” yachtsmen in competition with Plath and Tamaya at a price of around US$600, when a full-sized sized sextant by these makers could scarcely be had new for under US$1000. It had few features in common with its big brother, the Trommel or Drum sextant which retailed for about US$200 more, but presumably the pressure die cast aluminium alloy frame with rack cut directly into it, that they both had, was one feature that enabled Freiberger to undercut their Western rivals, or it may be that they were heavily subsidised.

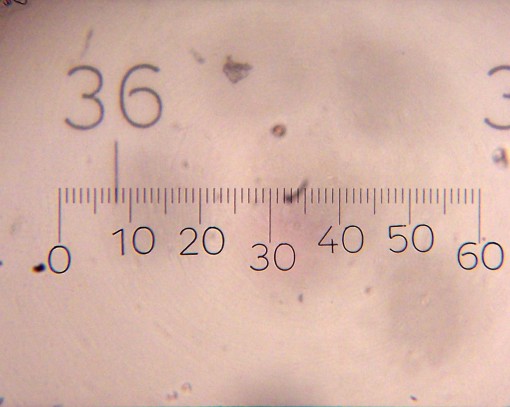

Another feature which is also unfortunately in common with the big brother is that some examples have large arc errors, sometimes up to 90 seconds. As the arc is calibrated every ten degrees, it is not difficult to make a graph of the errors to help in applying corrections. Others would argue that on a pitching and rolling yacht, errors of observation are likely to swamp errors of the instrument. Many Freiberger instruments, it must be said, have the negligible errors of their competitors.

In a contemporary handbook, written in a charming Engleutsch, the Yacht sextant was “destined for use on sporting and luxury ships… with conditions and requirements for accuracy …completely maintained though weight and volume of sextant have been reduced down to approximately half their former values. In consideration of aspects of beautiful shape and representativity, graduated arc and arc webbing have been modified that dimensional stability at extreme temperature differences and mechanical stress can be expected at the same time.”

In my description that follows, I will comment mainly on points that distinguish this sextant from the conventional, touching only briefly on parts that follow standard practice.

General arrangement (Figure 1)

The frame is certainly austerely functional and the limb has a radius of 142 mm against that of the drum sextant, which is about 170 mm, while its weight with its permanently mounted telescope is 860 G, compared to, say, the 1300 G of an alloy-framed Tamaya with a star telescope mounted. There are only three index shades and two horizon shades, quite enough for most purposes. The mirrors, which are interchangeable, both measure 59 x 29 mm. This is not the advantage that it might seems, as the horizon mirror is fully silvered, that is to say, there is no plain glass half, the horizon being viewed directly rather than through a thickness of plain glass. The edge can be fully protected with paint, whereas the junction between the silvered and unsilvered parts of the traditional mirror was always a weak point for sea water to attack the silvering. However, each half of a Galilean telescope “sees” only its own field of view: if half of the objective lens is covered over, half of the field of view is lost. With the traditional arrangement of mirrors, some of the light from the index mirror is reflected off the front surface of the plain part of the horizon mirror into the telescope, so that the images of the body and of the horizon to a large extent overlap. In this instrument, with the fully silvered mirror and a Galilean telescope, there is overlap of about one sun diameter (about half a degree) as opposed to about two and a half diameters for a full glass, and this may make for difficulties for an inexperienced or occasional observer.

Most modern sextants seem to have Galilean telescopes with about x 4 power with an objective of 40 mm, while the Yacht sextant has one of x 2.4 power, with an objective of 22 mm, so the field of view is about the same. Early yacht sextants had ordinary, second surface mirrors. One that I have seen from 1985 has first surface mirrors which give a slightly brighter image, imperceptible to the eye (which can just detect a doubling in brightness), but at times of poor contrast between the sky and the horizon, even small differences in brightness can make for a useful increase in contrast.

Figure 1 : Front view of Yacht sextant.

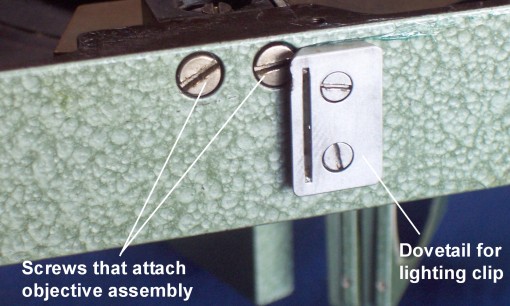

The arc is a sliver of screen-printed aluminium secured to the frame with glue and two pins which, rather surprisingly are made of steel. Predictably, in my example which had seen a lot of sea use, they had rusted and the glue had also given way. The telescope is a 2.4 x 22mm Galilean that focusses by rotating the objective lens mounting rather than the eyepiece and is less prone to go out of focus as the eye presses against the scope. The eyepiece is provided with a deep flexible rubber pad, a perhaps necessary adjunct for a lightweight telescope used on board a pitching and rolling yacht.

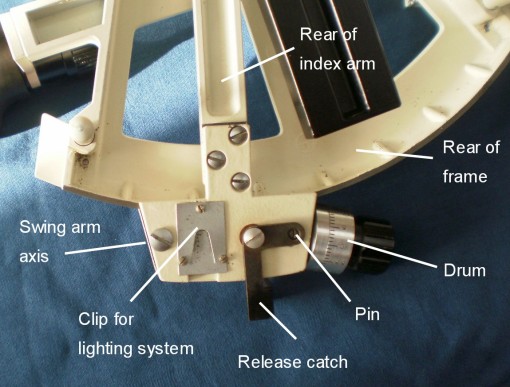

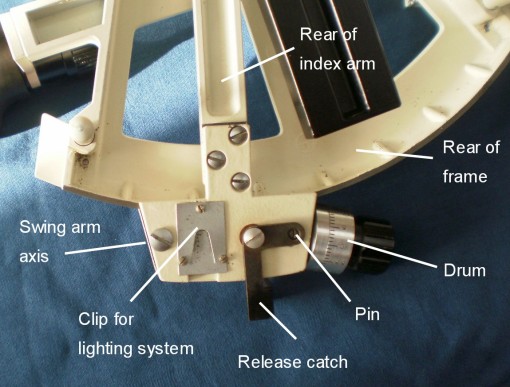

Figure 2 : Rear view of Yacht sextant

The rear view (Figure 2) shows that Freiberger retained the same arrangement for the index arm as in the Trommelsextant (and the Soviet SNO-T) siting it behind the frame out of harm’s way. To avoid having to have a bridging piece, the black anodised alloy handle is attached to the frame only at the top, by three screws. The release catch at the lower end of the index arm swings the worm out of engagement in the plane of the rack and, as will be seen, has a much simpler (and undoubtedly cheaper) arrangement than in its larger brother.

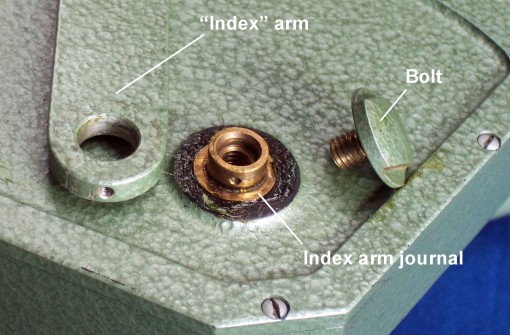

Index arm bearing

Figure 3 : A cornucopia of screws.

Removal of the handle reveals a sextet of screw heads beneath. Two pass through the bearing (strictly speaking, the journal) and attach the index mirror mounting to the deep flange on the other side. Four attach the index arm to the journal (journal : the part of a shaft that is enclosed by a bearing). Removing these allows the journal to be withdrawn. The fit is necessarily a very close one and care has to be taken that it does not capsize and jam. Figure 4 shows the bearing dismantled and it is seen that the large parallel bronze journal runs directly in the frame. There is no provision for taking up wear as none is to be expected in a slow-moving part with such large bearing surfaces.

Figure 4 : Index arm bearing details.

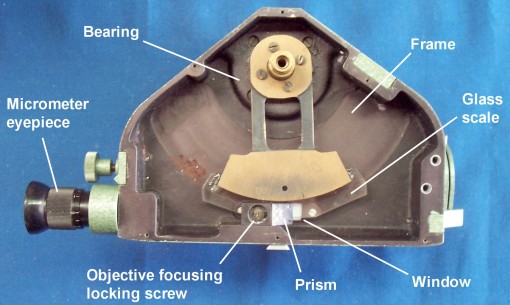

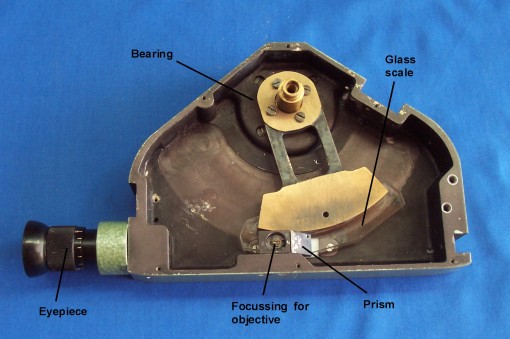

Worm and release catch

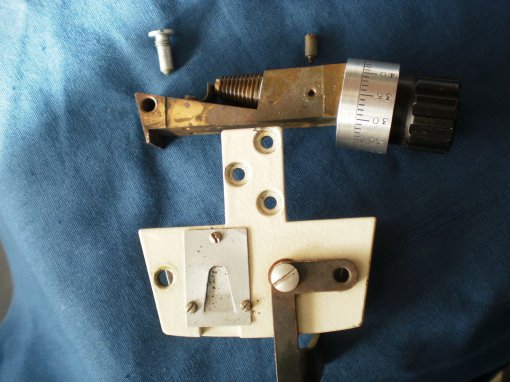

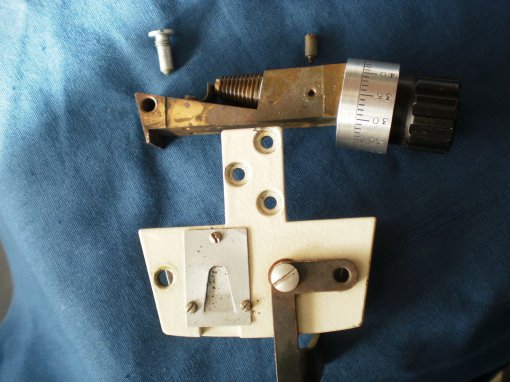

The Trommelsextant swung the worm out of engagement with the rack by having a relatively complex eccentric bearing that rotated the worm in its bearing out of the plane of the rack. Elegant though the method was, it must have been very expensive to produce. In the Yacht sextant, Freiberger have managed to give a large degree of protection to the worm by enclosing a substantial bronze swing arm with integral worm shaft bearing in a U-shaped alloy casting, that is attached to the index arm via a tongue and three screws (Figure 5). The shaft, immediately on emerging from its bearing, is enclosed by the micrometer drum and the knob for rotating it, so that a common consequence of dropping the sexant, a bent worm shaft, is avoided.

Figure 5 : Worm enclosure

The release catch is a cranked metal stamping. When it is operated, its end bears on a pin that passes through an oval hole in the enclosure casting into the swing arm, and presses the swing arm down agains a leaf spring that lies between the swing arm and the bottom of the casting. Upon detaching the casting from the index arm, some more details are revealed (Figure 6).

Figure 6 : Swing arm from above.

The bronze swing arm rotates about a pin for an axis (seen in Figure 5) and has a long and substantial bearing for the worm shaft. End float of the latter is prevented by trapping the worm between an L-shaped phosphor-bronze pre-load spring and a PTFE washer. The aluminium alloy drum, divided into minutes and attached to the knob by two screws, was heavily corroded and pitted in my example, and I was obliged to make a new one. The knob is retained on the worm shaft by a grub screw and a pin nut. Figure 7 perhaps allows a better appreciation of the internal workings of the release catch and swing arm.

Figure 7 : Side view of worm mounting.

Shades

The index shades are mounted directly into the frame, as shown in Figure 8.

Figure 8 : Index shades mounting.

They are mounted on a screw that has a longitudinal key way machined in it. The screw passes through a narrow tongue of the frame, through the shades and separating washers, through a Belleville washer (a washer having the characteristics of a short, stiff spring) and finally into the body of the frame. The separating washers have an integral tongue that fits into the keyway, so that forces from the rotation of one shade cannot be transmitted to the next. The Belleville washer provides enough friction for the shades to stay in the positions in which they are put. It might be thought that the friction could be varied by tightening the screw, but a transverse steel (!) taper pin prevents it from rotating. Driving it out places at risk the slender tongue of the frame which would pose great problems to replace it, if broken off.

The two horizon shades are mounted on a shouldered screw which also has a keyway and the separating washer also has a tongue that fits into the keyway to prevent it from turning (Figure 9). The screw is driven into a mounting block hard against its shoulder and it is only this that prevents the screw from undoing. A Belleville washer between the rearmost shade and the mounting block provides friction. Close inspection of Figure 9 shows that over time the convex side of the washer wears into the soft metal of the shade, resulting in loss of friction and a very annoying tendency for the shades to flop downwards out of position. This can be countered by means of a thin shim washer, whose internal diameter must be a little greater that the diameter of the unthreaded part of the screw, and care must be taken that the shim does not get trapped between the shoulder of the screw and the mounting block. Alternatively, the height of the Belleville washer can be increased slightly by making a depression in the end grain of a block of hard wood using a 12 mm ball bearing, resting the washer in the depression, placing the ball bearing on top and hitting it smartly with a hammer. This is likely to make the ball fly off into a remote recess of the workshop, but as it cannot now be reused for any other purpose, the loss is not a great one. When replacing the shades, they and the washers are mounted on the screw and it is started into position, with the concavity of the Belleville washer facing the mounting block. If the sextant is held with that washer facing upwards, it is then possible to wangle the hole in the washer over the shank of the screw before driving it home.

Figure 9 : Horizon shades mounting exploded.

Adjusting screws

The screws themselves are standard M2 screws with squared heads. They pass through split collets that are threaded on the outside and which screw into bosses projecting from the back of the mirror mountings. Each collet has a tapered tip that fits into a matching female taper at the bottom of the boss, so that when the collet is tightened, it closes up around the screw, thus increasing the resistance to the screw’s rotation or locking it if required (Figure 9). There is a clearance hole through the mirror bracket for the screw

Figure 10 : Adjusting screw, collet and tool.

Though the adjusting screws for the SNO-T and the Freiberger Skalensextant are superficially similar, anyone who treats them the same is in for an unpleasant surprise; and jammed, broken or stripped screws are a common occurence. In these sextants, the collets, which have coarse threads on the outside are not split, and the adjusting screws pass through threaded holes both in the collet and in the back of the bracket. The screws are locked by unscrewing the collet a little. The screw can be withdrawn by rotating the collet a little to find the position at which the screw is unlocked. Any attempt to fully unscrew the collet before the screw has left the thread in the mirror mounting inevitably causes damage. Some early Trommelsextants may have the same arrangement, so it would pay to proceed with caution if backing off the nut by half a turn does not release the adjusting screw.

If you have enjoyed reading this account, you will I am sure enjoy reading my book, The Nautical Sextant, available through booksellers, from Amazon or direct from the publishers, Paradise Cay and Celestaire.

You must be logged in to post a comment.