Wood

Wooden frames continued to be used for another 150 years for cheaper instruments or those where a high degree of accuracy was not required, for example, in finding latitiude by measuring the angular height of the sun above the horizon at local noon. Strictly speaking, these were octants, measuring up to 90 degrees, because no body has an altitude greater than this. By the middle years of the eighteenth century there was in England a push for greater accuracy of observations. Nevil Maskelyne, the Astronomer Royal had published in 1763 The British Mariner’s Guide, which contained an English translation of Tobias Mayer’s tables of predictions of the moon’s position in the sky, together with instructions on how to use them to fix longitude at sea. Since the moon moves across the sky at a different rate to the movement of the Sun and stars, it can be used as a sort of celestial clock by measuring the angle between the moon and another heavenly body. By comparing one’s local time with that derived from the lunar distance, say, at Greenwich, the longitude could be deduced. Unfortunately, the difference in rates of the movement between the moon and the other bodies is relatively small, so that a small error in measuring the angle results in a large error in the deduced longitude.

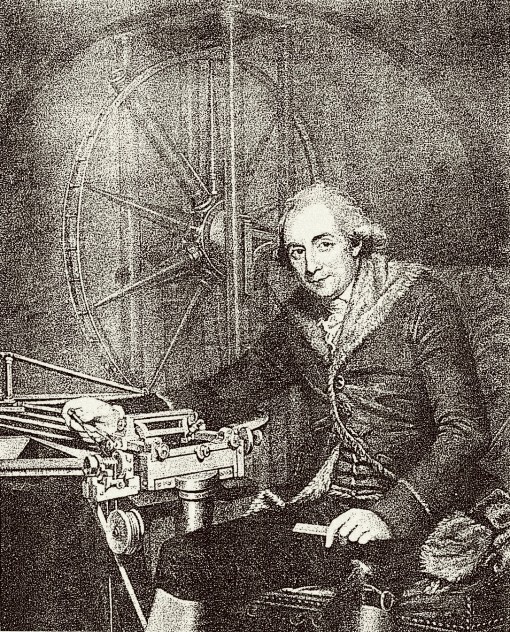

Wooden instruments were not capable of measuring the angles with the required degree of accuracy nor, for that matter, were hand divided instruments. Jesse Ramsden described his dividing engine in 1774 (see my post under Chasing tenths of an arc minute, September 2010) after which practically all sextants were machine divided. From about this time also, sextants, able to measure up to 120 degrees of an arc, started to be made of metal, as they could now be made smaller, while wood continued to be used for many of the lowly octants, more usually called Hadley’s quadrant or simply “a Hadley” . The wood used was usually heart ebony, a very hard, stable and dense wood (Figure 1), though mahogany was also sometimes used. The index arm (alidade), mirror and shade mountings were made of sheet brass, using techniques well established by the clock-making industry.

Bronze

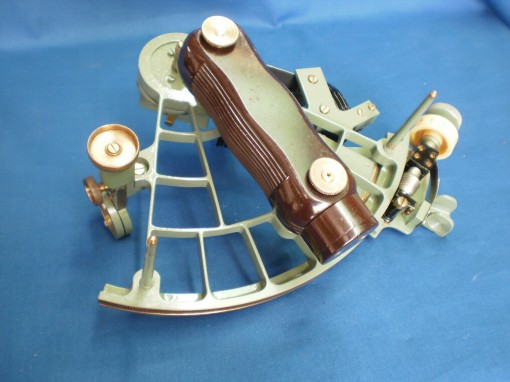

Though museum cataloguers often describe sextants as being made of brass, an alloy of copper and zinc, the metal used was bronze, an alloy of copper and tin. Sound castings could not be made in brass with the techniques and alloys of the time, whereas it is possible to make relatively large and intricate castings out of bronze. As the proportion of tin increases, the metal becomes harder and more rigid until, at a maximum of around 20 percent of tin it becomes known as bell metal. This is somewhat brittle and the bronze used for sextants contains about 8 to 10 percent of tin. Early metal sextants commonly had a limb of brass screwed on to the front of the frame and heads rivetted and filed flush (the heads are visible in Figure 2). Brass of the time was made by hammering and rolling into sheets and often had hard spots that could divert a scriber from its true course, so almost from the beginning, the divisions were made onto an arc of silver let into the limb. For a short period in the early 19th century, when platinum was cheaper than silver, platinum was used sometimes and, rarely, gold for the vernier. Ivory was used for cheaper instruments.

Brass

An exception to the use of brass for frames was the pillar sextant, produced almost entirely by Jesse Ramsden and by the Troughton brothers. Copying the techniques used for clock plates, two thin brass plates were held apart by numerous pillars of brass to give a relatively light and stiff frame.

Aluminium alloy

An electrolytic process for the smelting of aluminium was devised in 1866, converting the metal from one of great rarity and expense to something much cheaper, but the pure metal is soft and not suitable as a structural material. Nevertheless, sextants were occasionally made with aluminium frames in the late 19th century, usually as an experiment or for a special purposes.

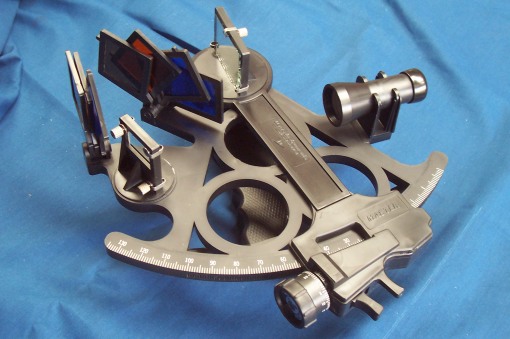

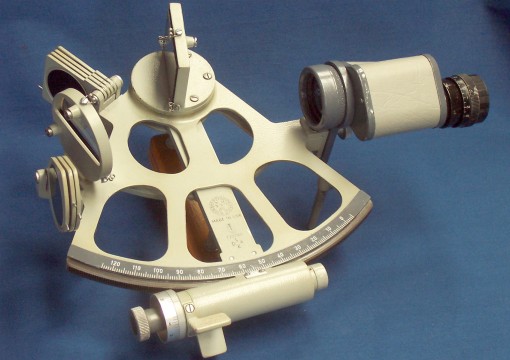

Early in the 20th century, hard and strong alloys of aluminium were developed. This, combined with the pressure die casting process, allowed manufacturers to mass produce aluminium alloy frames of about a third of the weight of those of bronze, with a strength and stiffness approaching or exceeding that of mild steel. Despite the availability of aluminium frames from the mid 1930s onwards, mariners on the whole continued to prefer bronze frames, regarding sextants with aluminium frames as cheap “knock offs”. The exigencies of the Second World War, however, required a much increased rate of production and, especially in Germany, non-ferrous metals were scarce. The US BuShips Mark II sextant in the USA and C Plath wartime sextant in Germany were produced in very large numbers and Tamaya in Japan also used aluminium in the later stages of the war. In the US and Japan, its seems that makers could not bring themselves to abandon bronze entirely for the rack, either attaching it with screws to the machined frame or casting it in place (Figure 3). C Plath, however, machined the rack directly into the aluminium frame, as did all post-WW II Russian instruments (Figure 4), with no consequences for accuracy and durability.

After the end of WWII, most makers reverted to making the frames either entirely of bronze (despite its inferior stiffness) or of aluminium alloy with a bronze rack. The USSR, however, made the frames for their SNO-M and their later SNO-T sextants entirely from aluminium alloy, with a bronze micrometer screw running in a rack cut directly into the frame (Figure 4, above). Both sextants performed well and the SNO-T was possibly the best sextant ever made.

The requirements of the frame are to unite the centre bearing with the arc or rack in a fixed relationship, to make provision for the attachment of shades, mirrors, handle and telescope and to do so without flexing or twisting. The axis of the index arm bearing must be square to the plane of the arc or rack and stay that way in use. The horizon mirror must also stay perpendicular. Nearly every sextant joined the bearing to the curved limb with two radii about 60 degrees apart and had one or more transverse bars that joined the two radii. At first there was no handle by which to hold the large frame, but as frames became smaller, the transverse bar was used as one of the points of attachment for the handle. The way the various subsidiary parts were attached to the frame varied greatly from maker to maker and they usually filled in the space between the radii and limb with sometimes fanciful frame work. There was probably little thought or experiment to determine whether one form of frame work was more rigid than another, though as knowledge of engineering structures improved it was probably appreciated that depth of the framework was an important contributor to stiffness.

Wooden frames

Figure 6 shows the rear of a typical wooden-framed octant of about 380 mm (15 inches) radius. It has the basic form described above and the position of the joints are shown by white lines.

The wood is heartwood ebony, a hard, dense, black and very strong African wood, resistant to rot. The index arm is of brass and the arc and vernier of ivory. Through tenon joints unite the radii to the limb and “blind” tenon joints are used elsewhere.

The joints of the curved transversal that unites the two radii are also blind. The part-radius between the transversal and the limb probably adds little to its rigidity and served as a handhold. It may come as a surprise to some readers that this instrument by Norie and Wilson dates from after 1843, the year of Norie’s death. It has shown essentially no advance, even in detail, from instruments dated a hundred years earlier. We may note in passing the unsatisfactory index arm bearing, which was very prone to stick-slip.

Brass frames

Bronze frames

While maintaining the basic form with two radii uniting the centre to the limb, there was a great variety of ways that the space in between was filled in. A sextant is generally used with the frame in a vertical position and has to resist distortion mainly due to its own weight. However, resistance to bending in the plane of the frame is relatively easy to measure, so that I have used that as a surrogate for general resistance to distortion. I illustrate the set up for comparing resistance to flexion in Figure 10. A 1 kg force is applied to the end of the index arm and the deflection measured by means of a dial indicator that reads to 0.01 mm.

A beam gets more resistant to bending as its depth increases and a substantial increase in bending resistance can be achieved with a relatively narrow vertical web. The frame of a mid- 19th century octant of about 200 mm radius shown in Figure 11 follows the pattern of its wooden predecessor with the addition of 10 mm deep ribs to radii and transversal of a mere 1 mm thickness.

This was not very resistant to bending when compared to some later 20th century instruments. Changing the shape slightly, as in the tulip frame octant of the same period shown in Figure 12 may have increased sales, but it did not increase stiffness.

In spite of the fairly heavy webs, it was no more resistant to bending than the sextant shown in Figure 13, which was sixty or seventy years its senior. Apart from the composite limb of bronze and brass, this sextant of 210 mm radius is, as it were, all webs of substantial 10 x 2 mm section, with the addition of screwed-on triangular bracing (the bare frame is shown in Figure 2).

Troughton and Simms, a noted maker of surveying equipment, obviously appreciated the benefits of triangulation in making a structure stiff, and the sextant of 200 mm radius shown in Figure 14 flexed about 40 percent less than the ladder framed sextant by Hughes and Son from the same period, shown in Figure 15. In both instruments, the webs are about 10 x 2 mm in section, but in the Troughton and Simms sextant, the “beams” are also 2 mm thick and average about 15 mm wide, so the contribution to resistance to flexing may not come simply from the pattern of the webs.

A popular pattern for the frame, which seems to have given great rigidity, was the three circle, used briefly by C Plath on their Drekreis vernier sextant, by the two major English makers, Hughes and Son and Heath and Co, and by La Filotecnica, an Italian company, little known for making sextants (Figure 17). Plath, Tamaya and the major US maker of sextants prior to WW II, Brandis and Sons, settled on various patterns of ladder-like lattices for their bronze-framed instruments (Figure 18).

Aluminium alloy frames

As noted above, by the mid 1930’s all the major makers had introduced aluminium alloy frame, made by the pressure die-casting method. In this process, molten metal is injected under high pressure at several points into a closed die or mould and the pressure maintained until the metal freezes. This produces dense, uniform, castings, free of hard spots or bubbles and having a surface finish as good as that of the interior of the die, but as importantly, the material used is about twice as resistant to bending as bronze and about its equal in resisting corrosion.

Thanks to the generosity of Ken Gebhart, I am able to illustrate the manufacturing steps in the production of an alloy frame with bronze rack, for the fabulously costly US Navy Mark III sextant, made in Milwaukee under licence from C Plath. Figure 19 shows the frame fresh from the die except that the risers for the escape of air and gases and the injection points have been “fettled” off. Also shown is the part-machined bronze rack. Flash, the thin slivers of metal where it has seeped between the two halves of the die is then cleaned off and both faces of the casting machined flat. The hole for the index arm bearing is then reamed out to finished size and this hole is used to locate the frame for further machining operations. For example, to turn the seat for the rack (Figure 20) the hole is located on a well-centred and close-fitting spigot on the turning machine.

The rack casting is then attached to the alloy frame with screws (Figure 21) and finish-turned to size before being transferred to a hobbing machine to have the teeth of the rack generated. Again, the central hole is used to locate the composite frame on the machine to ensure that the teeth of the rack will be truly centred. Figure 22 shows the finished frame, ready to have the index arm bearing and other parts fitted.

Most makers of alloy framed instruments copied the forms of bronze predecessors, mainly ladder patterns as in the Mark III above, though during the Second World War C Plath settled on a standard triangulated pattern (Figure 23). This was copied in the Soviet SNO-M sextant and the Chinese GLH 130-40 sextant, while Plath reverted to the ladder pattern when sextant production resumed in about 1950.

Freiberger Prazisionsmechanik, who as far as I know had never made sextants prior to WW II, applied their expertise in surveying instruments to produce their Trommelsextant (Figure 24) and the radically different Skalen sextant (Figure 25). The Freiberger sextants , together with the Soviet SNO-T, closely similar to the Trommelsextant, had exceptionally rigid frames, with material concentrated around the edges, a stiffening central web and the handle attached directly to the edges of the frame via a sub-frame.

The WW II Plath instruments and the post-war SNO-M, SNO-T and Freiberger instruments all had the rack cut directly into the frame with a bronze worm. This combination seems to have stood the test of time, as a well-used 1982 SNO-T sextant I once calibrated had no non-adjustable error of greater than 11 seconds. Nevertheless, many makers, including Plath and Tamaya, continued to fit their sextants with bronze racks, presumably because their customers preferred them that way, despite the extra expense involved in making them. A demand continued for wholly bronze frames. Despite their theoretically inferior properties, they perform just as well.

One professional mariner of my acquaintance, a retired deep-sea trawler captain, says that he preferred a bronze framed instrument because of its greater weight, which he felt gave it extra stability when taking sights in rough weather. A bronze rack adds about 150 G to the weight of the frame, while a typical bronze frame, at 600 G is about 250 G (abut half a pound) heavier than a typical alloy frame.

You must be logged in to post a comment.