See also the post for 4 November, 2012, “Fleuriais’ Marine Distance Meter”.

Some time in the first ten years of the twentieth century, possibly in 1907, Carl Plath introduced the micrometer sextant to navigators. It was not claimed that the micrometer sextant was more accurate than the vernier type, rather that it was easier and quicker to read. The National Maritime Museum at Greenwich has an example dating to about 1917: http://www.nmm.ac.uk/collections/explore/object.cfm?ID=NAV1130&picture=1#content. The instrument shown is missing the fixed part of the release catch, not the first I have seen in this condition.

The micrometer reads to one minute and the mechanism of the Plath release catch appears to have remained the same right through to the Second World War and beyond, when manufacture was continued as the USSR Navy SNO-M sextant. From about 1940, Tamaya also began to produce a sextant that was in every respect identical to Plath’s design. The following photo is of an early Tamaya, serial number 606 (Figure 1).

Figure 1 : Early Tamaya micrometer sextant

Figure 2 shows a detailed view of the micrometer mechanism. If you look at the preview of The Nautical Sextant, you will see its close similarity to the USSR SNO-M, which in turn is identical in practically all respects to the wartime C Plath.

Figure 2 : Details of Plath-type micrometer mechanism.

Apart from the scale illumination system, the sextant could be a C Plath of the same period. Perhaps it was. In the nineteenth century, it was common for sellers to put their own name on a sextant made by someone else and Tamaya may have continued the practice into the twentieth.

In about 1909 Heath and Co. introduced their “Hezzanith endless tangent screw automatic clamp” which incorporated all the elements of a micrometer sextant but without a micrometer drum. It allowed rapid positioning of the index arm followed by fine adjustment, but the readout was still from a vernier main scale. The patent document concluded:

Figure 3: Heath’s Patent rapid release clamp

However, C Plath may well have preceded Heath and Co, for Brent Evers recently sent me some photogaphs of an instrument in his possession that differs in no essential respect from Heath’s rapid release mechanism . The instrument frame is the Dreikreis (three circle) pattern (Figure 4) .

Figure 4 : C Plath Dreikreis sextant with rapid release clamp. Copyright Brent Evers, with permission.

There is a finely skew-cut rack on the back of the limb, with which a worm engages. The worm runs in bearings on a swinging plate between two centres, so that it can be swung out of engagement with the rack against pressure, by squeezing two knobs between finger and thumb. A helical spring between the knobs keeps the worm in engagement. A leaf spring provides axial preload to eliminate end-float of the worm spindle (Figure 5)

Figure 5 : Detail of Plath rapid release mechanism. Copyright Brent Evers, with permission

The near-identity of the two mechanisms is very evident from even a cursory inspection of Figure 6, which details Heath and Co’s patent rapid release clamp. The only point of difference is that Heath used a folded leaf spring between the two release clamp knobs to keep the worm in engagement.

Figure 6 : Heath and Co’s rapid release clamp mechanism

I am inclined to believe that Heath copied from Plath rather than the other way around, as the Plath instrument has a serial number in the low one hundreds, which would place it firmly in the nineteenth century, and the parts of the swinging plate have been fabricated, rather than employing a casting as Heath did. The Plath instrument may even have been a prototype. However, the serial number, placed at the left end of the limb, may have been from a separate series, as the sextant also has the stickman “Sunseeker” logo (registered in 1905) and is named “C PLATH HAMBURG” in the centre of the limb, in their very characteristic font. But we know that Plath had introduced a far superior design of micrometer mechanism by 1908, so it is most likely that Heath copied a mechanism that Plath had abandoned.

Note: (added 21 July 2011) I have since come across a Plath instrument with a serial number that places it in the late 1920s, though it has an archaic Plath frame. It has the same fine adjustment mechanism as the apparently earlier instrument.

In the early thirties, Heath and Co, by now merged with W F Stanley and Co., made the logical step of increasing the pitch of the rack and adding a micrometer drum:

Heath and Co was unusual in placing the rack on the back of the limb, whereas all other makers placed it on the edge, including Brandis, who by 1931 had produced a micrometer sexant of conventional design.

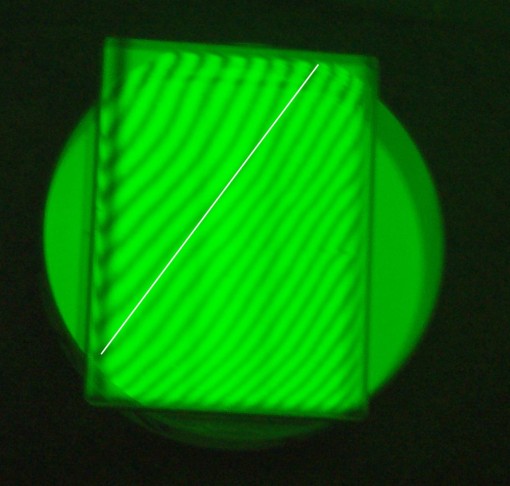

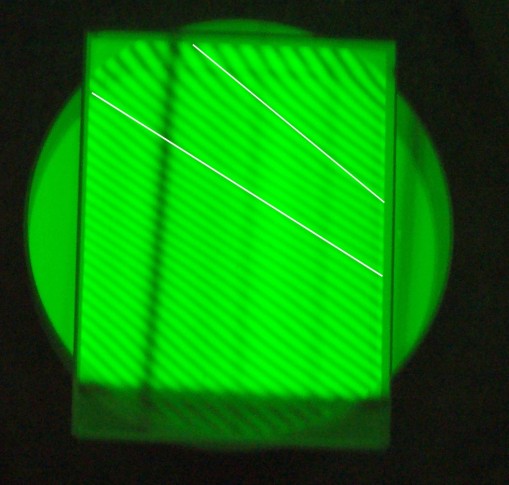

By the mid 1930’s, the other main sextant maker not mentioned so far, Hughes and Son, had begun to produce a micrometer sextant. Until recently, I had thought that this had arrived without an intermediate step between the vernier and micrometer, but a few days ago a “missing link” came into my hands. It seems at first sight to be a typical Hughes three ring vernier sextant, but the rear edge of the limb is provided with a rack and there is a micrometer worm with release catch, but no micrometer drum. Unlike nearly all other micrometer sextants except the USSR Navy SNO-T and the Italian Filotecnica Salmoiraghi, the micrometer worm is cylindrical rather than conical, in this case because there was no need to angle the shaft to accommodate a micrometer drum. The pitch of the worm is 18 turns per inch, so a micrometer drum divided into 60 arc minutes could easily have been added, except that the radius of the rack was rather too large, at about 6.7 inches (170 mm). The following three photographs give details of the mechanism of this rare sextant, whose serial number places it in 1931*:

Micrometer, front view

Micrometer, rear view

Micrometer, exploded view

The final version of the Hughes micrometer, continued right until the end of manufacture in the late 1960’s, is shown below. The conical worm is still of 18 t p i (M 1.41), but the pitchcircle radius of the rack has been reduced to 6.366 inches (161.70 mm).

Hughes micrometer, final version

Quite why makers other than C Plath were slow to introduce the micrometer is not clear. It was described by Hero of Alexandria, so was not patentable. Perhaps navigators of the time were conservative.

Lovers of detail will find much more about the detailed structure of the nautical sextant in my book, The Nautical Sextant .

* I have since come across the same model with a 1925 serial number.

You must be logged in to post a comment.