The preceding posts cover : C Plath Micrometer Sextant; A Damaged Rising Piece”, “SNO-T Mirror Bracket Repair”, “A Worm Turns”, “The case of the broken screw”, and “Worm with wrong thread angle?

Following the end of the Second World War, in November 1948 the venerable firm of Carl Plath was dismantled and its machinery distributed as war reparations, but by the autumn of 1950 it was able again to exhibit sextants at the Paris Shipping Salon. By the time Theodor Plath celebrated his 85th birthday in November 1953, the firm of C Plath was making between 1200 and 1500 sextants a year. About a month ago I received a C Plath sextant made in that year and have been spending some of my leisure time in restoring it.

Although the seller described it as being “in good condition”, this was far from the case, as there was widespread corrosion of screw heads, the mirrors had decayed, the index arm was jammed solid by verdigris and the release catch could not be operated, as the micrometer swing arm was seized solid. To add to the sextant’s woes, it had broken away from its moorings in its black bakelite case and bent the micrometer shaft as well as breaking off part of the plastic micrometer thimble. When buying second hand sextants, I routinely urge the sender to use plenty of packing inside the case to guard against such accidents, but on this occasion, my request had fallen upon deaf ears. As will be seen later, there was a hidden problem that became apparent only when I calibrated the instrument after restoring it.

Plath’s 1953 instrument showed little difference from instruments 20 years older. The bronze ladder frame of 162 mm radius had a conventionally placed rack and the design of the micrometer mechanism had not changed since it was first invented by the firm in about 1907. Though other makers made variations on the theme, the design was very sound and was copied, slavishly by Tamaya, and with minor modifications in attempts to have points of difference, by other makers.

In common with Tamaya, C Plath early realised the importance of light grasp in the optics and had large mirrors with telescope apertures to suit. My instrument came with a 6 x 30 prismatic monocular which gives an erect, bright image with a large field of view. Submariners of the US Navy in the Pacific Theatre in WW II had noted that by using such a monocular with their sextants, it was often possible to take accurate star sights in darkness, provided the observer’s eyes were fully dark adapted. Presumably, the experience of U-boat navigators was much the same and noted by C Plath, or there may have been liaison with Tamaya during the war. The latter firm supplied some instruments with a 7 x 50 monocular

My instrument was supplied with an astigmatiser in place of one of the index shades (Figure 1). This is a cylindrical lens that draws out the image of a star into a line. The axis of the cylinder is arranged so that the line is horizontal when the sextant is held with the frame vertical. According to Dutton, this can be of use when observing bright stars or planets with a dim horizon, though it probably comes into its own mainly when used with a bubble horizon.

Figure 1 : Astigmatising shade

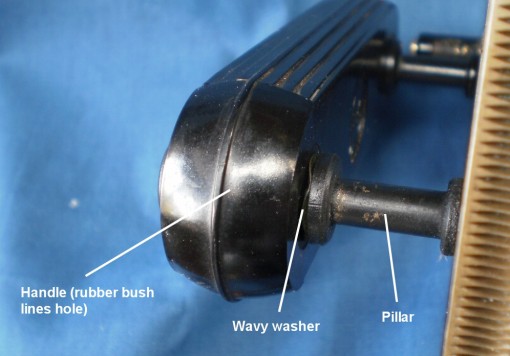

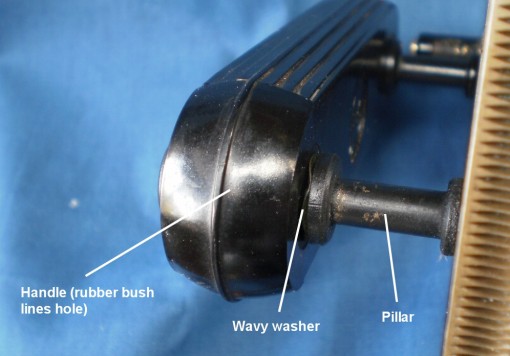

As usual, my first task was to remove all the main fittings from the frame: mirrors, shades, telescope mounting bracket and handle. The structure of these fittings was conventional, with the exception of the handle, which was fixed rigidly to the frame at the top but at the bottom made contact with it only via a rubber bush and spring washer (Figure 1). I assume someone had the idea of mounting the handle kinematically in this way to avoid redundancy of support and the introduction of additional strains to the frame if the handle should expand at different rates to the frame. It was not copied by others.

Figure 2 : Kinematic handle mounting

With the parts that stick out removed, I could then swing the index arm out of engagement with the rack, and remove the index arm with micrometer mechanism and bearing journal. Strictly speaking, the shaft enclosed by a bearing is the journal, while the enclosure is the bearing, but the whole assembly is often referred to as the bearing. At this point, the journal parted company with the thick brass disc on which the index mirror sits. It had been silver soldered in place during manufacture, but corrosion had made its way into the joint and the battering the instrument had received in transit was probably the last straw.

Before proceeding with the micrometer mechanism I thought it best to fix this problem. To a large extent, interference fits and hard soldering have been replaced in industry by the use of anaerobic industrial adhesives. These are usually based on cyanoacrylates with an inhibitor that prevents polymerisation by water vapour in the presence of oxygen. In the absence of oxygen, the adhesive sets hard and strong. While it was possible to remove all the verdigris from inside the disc and from the journal, the fit was a little loose, so I took advantage of the gap-filling properties of Loctite 680 high strength retaining compound. The disc was attached to the index arm with three screws. Once these had been removed, a little wangling separated the parts. While it is not absolutely essential that the journal should be square to the disc, it does make life easier, so I used a lathe set up as a makeshift jig to maintain the parts square to each other while the adhesive cured (Figure 3). The disc is held squarely in the chuck, while a tail centre is brought up to the centre hole in the end of the journal. As an aside, Loctite seems to cure exceptionally quickly when in contact with brass, sometimes within seconds, so it is useful to have a dry run to check that assembly can be finished without the adhesive curing while the parts are still in a partially assembled condition.

Figure 3 : Journal repair

As mentioned above, the design of Plath’s micrometer mechanism remained unchanged for many years, but as the twentieth century drew to a close, manufacture moved in the direction of greater simplicity (see previous post in this section). Figure 4 shows the general arrangement, together with the internal structure of the front bearing, which has to accomodate axial as well as radial loads.

Figure 4 : Micrometer mechanism

The worm shaft rotates within two bearings carried on a swing arm chasis which itself swings about a bearing, so that the worm can be swung out of engagement with the rack against the pressure of a leaf spring, which normally holds the worm firmly engaged with the rack. A collar on the worm shaft is held against a thrust face in the front bearing by an axial pre-load spring that presses against a ball bearing let into the rear end of the shaft. These two springs take up all clearances (apart from a thin film of oil or grease) so that there is no lost motion when the worm engages the rack or rotates.

The front bearing with its thrust face is made in two parts that are held together with four screws and located by two dowel pins visible at top left and bottom right of the lower half-bearing. The hole down the centre of the bearing would have been bored with the two parts assembled together and then split for assembly. Machining the recess for the thrust collar I would rate as rather a difficult boring operation, and this probably accounts for its later abandonment as labour and other costs rose.

After dis-assembling the mechanism down to the last screw and cleaning off all the verdigris, dried oil, grease and dirt, and putting it together again, it quickly became apparent that all was not well. Rotation of the micrometer shaft was very stiff and the resistance varied. The damaged micrometer drum wobbled as it rotated and it was very clear that the micrometer shaft was bent. Figure 5, in which the rear end of the shaft is held in an accurate collet in a lathe, shows that there was a “run out” or eccentricity of the shaft just beyond the front bearing of 0.2 mm, while none was apparent in the rear half of the front bearing.

Figure 5 : Runout of bent micrometer shaft.

While engineers routinely straighten bent shafts using large hydraulic presses, straightening is not really an easy option for parts of small precision mechanisms, though one might attempt it in desperation. If one is well-equipped, the simplest option is to renew the whole worm shaft. For this a lathe with a taper turning attachment is needed together with the ability to cut a thread of 1.4 mm pitch, a non-standard thread. I have touched on taper thread cutting in a previous post (A Worm Turns, 6 July 09). The other main challenge is to form the collar between two cylindrical bearing surfaces. The cutting tool, shaped like a broad parting tool, necessarily takes a comparitively broad cut on a slender shaft, with a risk of chattering that will leave a poor finish. Figure 6 shows the bearing surface being formed with the shaft held between centres and with solder wire wrapped around it to help reduce the tendency to chatter.

Figure 6 : Forming second half-bearing

The next task I tackled was to make a new micrometer drum and thimble. I started by straight knurling a length of 26 mm aluminium alloy bar and them Loctited (if such a verb exists) a larger collar on to it. Once the Loctite had cured, I turned the collar down to size and then, while everything was still nice and rigid, scribed sixty divisions. Figure 7 shows this in progress.

Figure 7 : Dividing the drum

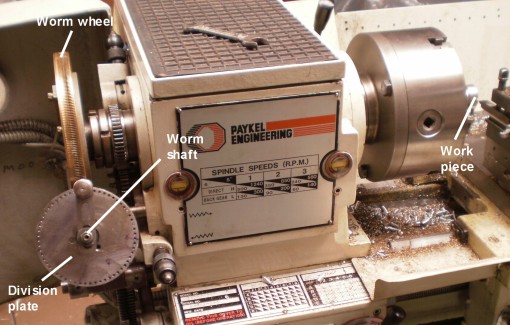

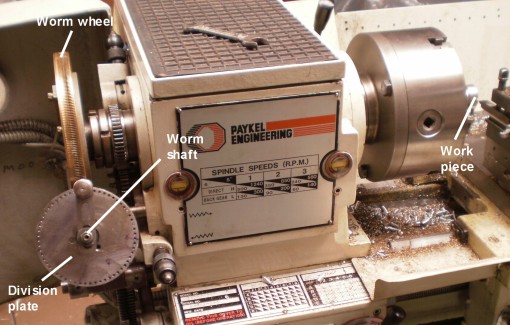

Normally, dividing would be carried out on a separate dividing head or the divisions would be rolled into the surface, but I often use a home-made attachment on the headstock of the lathe itself as it ensures concentricity (Figure 8). A worm engages with a worm wheel having 360 teeth on the back end of the lathe spindle, so six turns of the worm advances the drum through one division. It is necessary not to lose concentration during this dividing process as the discovery that you have lost count somewhere is usually delayed until you have cut the last division and find that it is too small or too large.

Figure 8 : Headstock dividing.

The next task also needs concentration if exclamations such as “How very unfortunate!” are to be avoided when a wrong or upside down number is punched. Number punches are best guided by some sort of jig if an amateurish result with uneven alignments is to be avoided. Figure 9 shows a primitive possibility which consists of a square bar with a hole in it and a 6 mm screw whose end provides a flat surface within the hole to prevent the punch from rotating. The dividing attachment and the top slide of the lathe are used to position the numerals. Some numerals need harder blows than others and this requires a little practice on a piece of scrap material to get things right.

Figure 9 : Punching numbers.

With divisions and numbers safely out of the way, the part can be turned to its final shape, the central hole drilled and reamed and the combined drum and thimble parted off. The original drum was white with black markings, but since taking the photographs for Figure 10, I have been persuaded by my wife to prefer white markings on a black ground. The ground is sprayed on first and allowed to cure thoroughly. The divisions and numerals are them carefully scraped free of paint and filled in by painting over with the contrasting colour and wiping off with a single layer of thin rag stretched over a finger tip. Thicker or loose rag tends to wipe the paint from the bottom of the divisions or numbers. Figure 10 shows the result.

Figure 10 : New drum.

I have covered making new rectangular mirrors in a previous post (New Sextant Mirrors for Old, 11 February 09). Cutting cirular mirrors for the horizon mirror will be the subject of a future blog when I have fully developed the method.

Overhauling the monocular revealed an interesting detail, presumably based on experience of keeping the instrument waterproof in the very adverse conditions found on U-boats during WW II. Figure 11 shows the construction of the objective lens mounting and the front plate of the monocular. Engineers will recognise this as a form of labyrinth seal in which contaminants (in this case sea water) have to follow a circuitous route, meeting mechanical barriers and thick layers of grease on the way.

Figure 11 : Labyrinth seal of monocular objective.

Spray painting the frame and other individual parts completed the restoration. I use CRC Black Zinc, as it is tough, relatively quick curing and has a semi-matte finish very much like the original. I have covered ways of masking shades and other parts in the Sextant Restorations category. I always have to restrain my impatience and allow at least 24 hours for the paint to harden up enough to allow reassembly, but the paint takes a few more days to reach full hardness.

Normally, reassembly and tidying up the case would complete a restoration, but I recently completed a sextant calibrator that allows me to calibrate a sextant in about half an hour (Chasing Tenths of an Arcminute), so I checked out my new-looking sextant. The results shown in Table 1 were not compatible with C Plath’s high reputation and it was very unlikely that the sextant had left their factory with such large errors, exceeding a minute in two instances.

Table 1 : Sextant errors, first run.

Errors like this, increasing rapidly as the sextant reading increases, suggested that the axis of the index arm bearing was not at right angles to the arc and, by implication, the frame. A quick check on a surface plate with cigarette papers showed that the limb was slightly bowed, concave to the front, and the machined rear surface of the framewould not sit squarely on the plate without rocking slightly. The frame, it seemed, was bent but in which direction? I removed the index arm bearing to check that it was seated properly in the frame and it was. I normally advise against doing this without very good reason, but I felt that I could scarcely make the instrument worse, so I went ahead and checked. Finally, I made a mandrel to fit the taper in the bearing and checked it with a square against the frame (Figure 12).

Figure 12 : Leaning mandrel.

While it was only possible to check where there was frame on which to sit the square, it appeared that the rear edge of the frame was bent, so I held the zero end of the limb in a vice and gave a hard pull backwards on the apex of the sextant. My first attempt was lucky, as Figure 13 shows. The limb now trapped cigarette paper throughout its length and the frame no longer rocked on the surface plate.

Figure 13 : Uprighted mandrel

Table 2 : Sextant errors, second run

Recalibrating it gave the results shown in Table 2. While the errors above 90 degrees are perhaps rather large for this class of instrument, in practice only a Lunartic or a surveyor would complain about them, and for its era are perfectly acceptable. Certainly, it is “Free from error for practical use“, which is all that C Plath was ever prepared to say.

So, dropping a sextant with a bronze frame can bend it, as well as causing other, more obvious damage, but it need not be a death sentence, with the instrument condemned to hang on a living room wall or behind a bar with a nautical theme. With love and care and some surgery, it can regain its good looks and live a normal life again (Figure 14).

Figure 14 : Sextant no. 3****6 returns to a normal life.

If you have enjoyed reading this account, I am sure you will enjoy reading my book “The Nautical Sextant“, and your purchasing it will help me to ensure that more sextants are restored to a normal life.

You must be logged in to post a comment.